- Englist

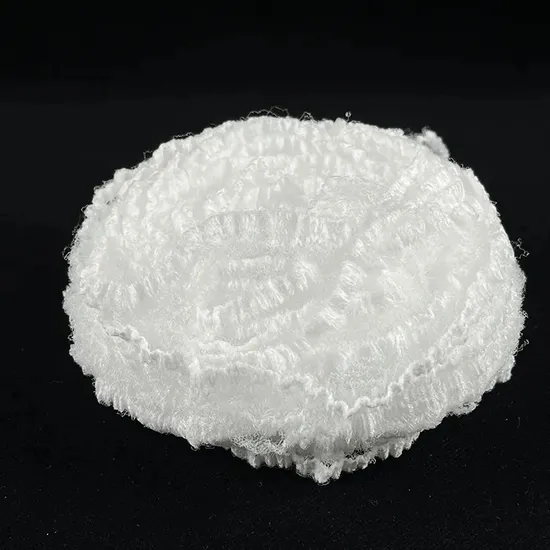

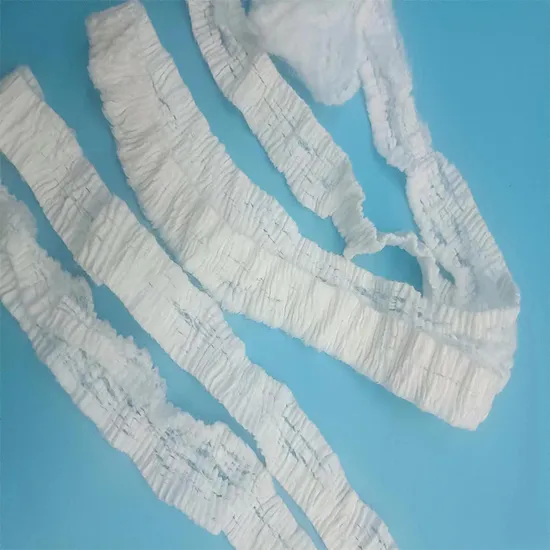

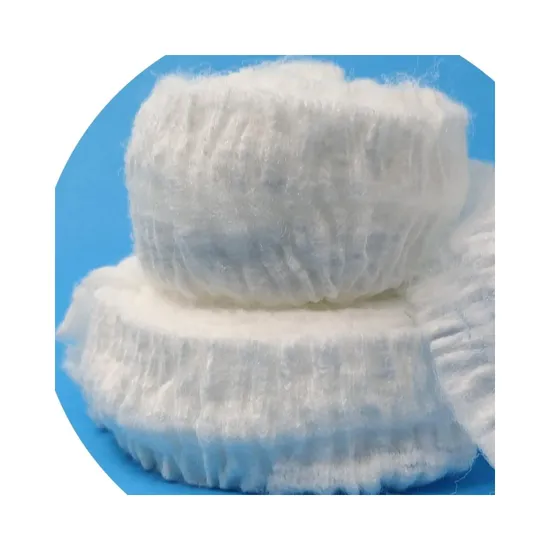

Cellulose acetate tow is a fibrous material made from cellulose, derived from wood or cotton, and chemically modified with acetic acid to form cellulose acetate. It is widely used in the production of cigarette filters, where its porous structure effectively traps harmful substances and particulates, improving air quality for smokers. The fibers are highly absorbent and can be easily processed into various shapes and sizes, offering excellent versatility in manufacturing.

Cellulose acetate tow is lightweight, biodegradable, and environmentally friendly, making it a preferred choice in sustainable products. The material is also used in the textile industry for the production of nonwoven fabrics, offering a soft texture, durability, and resistance to shrinkage. Its high strength, coupled with its ability to be dyed and treated, makes it suitable for a range of applications, from medical products to personal care items.

What Is Cellulose Acetate Tow Used For?

Cellulose acetate tow is a versatile material with a variety of uses across several industries, primarily due to its unique combination of properties such as biodegradability, absorbency, and ease of processing. One of its most prominent uses is in the production of cigarette filters. The tow is processed into fibers that are then used to make the filter element in cigarettes. Its fibrous structure allows it to effectively trap harmful substances such as tar and nicotine, reducing the impact of these chemicals on the smoker. Additionally, cellulose acetate tow is biodegradable, making it a more environmentally friendly option compared to other synthetic filter materials.

Beyond the tobacco industry, cellulose acetate tow is widely used in the textile industry. It can be processed into nonwoven fabrics for use in a variety of applications, such as medical products, including surgical gowns, masks, and wipes, thanks to its softness, strength, and absorbency. The material’s versatility also extends to the production of filters for air and water filtration systems, where its fine, porous nature allows for efficient particle capture.

In the personal care industry, cellulose acetate tow is used to make items like cosmetic pads and diapers, where its absorbent properties make it ideal for these applications. It’s also used in wipes for cleaning, as the fibers effectively hold liquids and other substances, providing a durable yet gentle solution.

Additionally, cellulose acetate tow is employed in industrial applications such as the manufacturing of reinforced plastics and composite materials. These materials benefit from the tow’s high strength, light weight, and ability to be easily molded into different forms. In summary, cellulose acetate tow is valued for its wide range of applications, from filters and textiles to medical products, making it a key material in multiple industries.

Why Is Cellulose Acetate Used In Electrophoresis?

Cellulose acetate is used in electrophoresis because it provides a stable, uniform, and semi-permeable medium for separating molecules like proteins and nucleic acids. Its porous structure allows charged particles to move through it under an electric field, enabling effective separation based on size and charge.

Cellulose acetate membranes are chemically inert, easy to handle, and produce clear, sharp bands, which helps in accurate analysis. They are also compatible with various staining and detection methods. Additionally, the membranes are durable and can be stored or archived after use. These properties make cellulose acetate a popular choice in clinical and research laboratories.