- Englist

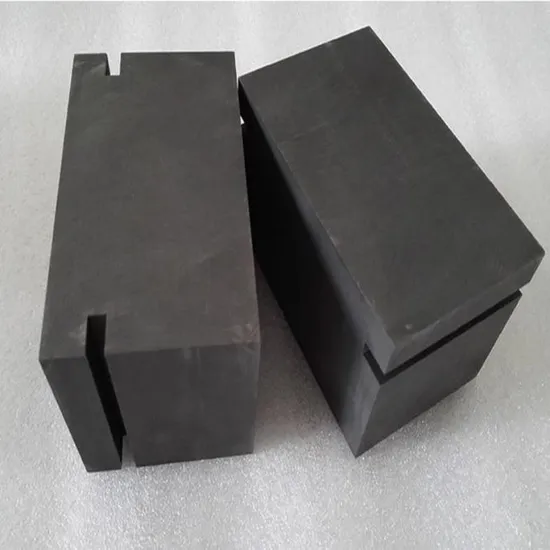

Graphite blocks are solid, high-performance materials made from high-purity graphite, known for their excellent thermal and electrical conductivity, as well as their high resistance to heat and wear. These blocks are commonly used in industries such as metallurgy, electronics, and energy, where high-temperature stability and durability are essential. Graphite blocks can withstand temperatures of up to 3000°C, making them ideal for use in furnaces, molds, and other high-heat environments.

The material's natural lubrication properties also make graphite blocks effective in reducing friction in mechanical applications, such as bearings, seals, and sliding components. Additionally, graphite blocks are resistant to oxidation and chemical corrosion, enhancing their longevity and reliability in harsh industrial settings.

What Are Graphite Blocks Used For?

Graphite blocks are versatile materials used in a wide range of industrial applications due to their unique combination of properties, such as high thermal and electrical conductivity, resistance to high temperatures, and chemical stability. One of the primary uses of graphite blocks is in the metallurgical industry, where they serve as components in furnaces, crucibles, and molds. Their ability to withstand extreme temperatures—up to 3000°C—makes them ideal for use in high-heat environments, such as melting and casting metals, including steel, aluminum, and other non-ferrous alloys.

In addition to their use in metallurgy, graphite blocks are crucial in the electronics industry. Due to their excellent electrical conductivity, they are used in the production of electrodes for electric arc furnaces and in electrical contacts for various devices. Graphite blocks are also commonly used in thermal management systems, including heat exchangers and heat sinks, where their high thermal conductivity helps regulate temperature in sensitive equipment such as semiconductors and power electronics.

Graphite blocks are also employed in lubrication applications. Their self-lubricating properties reduce friction in mechanical components such as bearings, seals, and sliding parts, contributing to smooth operation and increased lifespan. This makes them valuable in industries such as automotive and machinery manufacturing.

Furthermore, graphite blocks are used in the aerospace and nuclear industries, where their heat resistance and structural integrity under extreme conditions are essential. They are employed in thermal protection systems, nuclear reactor components, and spacecraft parts, where high-performance materials are required for safety and efficiency.

The ability to machine graphite blocks into various shapes and sizes also makes them highly adaptable for custom applications, whether in precision tooling or high-performance materials. Their resistance to oxidation and chemical corrosion, combined with their high strength and conductivity, make graphite blocks indispensable in many demanding industrial processes.

What Are Graphite Blocks Used For In Art?

Graphite blocks are used in art for sketching, shading, and large-scale drawings. Unlike regular pencils, graphite blocks allow artists to cover wide areas quickly, making them ideal for creating bold lines, gradients, and textures. They can be used on their sides for broad strokes or on the edges for fine details.

Artists often use graphite blocks in figure drawing, landscapes, or expressive, abstract works. They come in various hardness levels, from soft (darker) to hard (lighter), allowing for a range of tones. Graphite blocks are also great for blending and smudging techniques, giving artworks a smooth, dynamic look.