- Englist

Electrode paste is a critical material used in the production of electrodes for electric arc furnaces (EAF) and other high-temperature processes. Made primarily from a blend of petroleum coke, coal tar pitch, and other additives, electrode paste is designed to provide excellent conductivity and durability in extreme heat. It is used to form the paste around electrode rods, enhancing their performance in smelting and refining applications.

The paste has excellent bonding properties, ensuring that the electrode remains intact during high-power electrical currents and intense heat. Its high thermal stability allows it to withstand temperatures up to 3000°C without degrading, making it ideal for industries like steel manufacturing and foundries. The material also has good resistance to oxidation, which contributes to the longevity and reliability of the electrodes during prolonged use. Electrode paste is essential in ensuring efficient, consistent operation of electric arc furnaces and other high-temperature systems.

How Do You Make Electrode Paste?

Preparation of Raw Materials: The primary ingredients include petroleum coke, which provides the carbon content, and coal tar pitch, which acts as a binder. These materials are sourced based on their quality and specific requirements for the intended application. Other additives, such as plasticizers or modifiers, may be included to enhance the paste's properties.

Mixing: The raw materials are then carefully mixed in specific proportions. This is usually done in a high-energy mixer, where the petroleum coke is ground to a fine powder to improve its homogeneity and mixing with the binder. Coal tar pitch is heated until it reaches a liquid state, allowing it to properly bind with the coke powder.

Heating and Blending: The mixture is heated to a controlled temperature, typically between 120°C to 180°C, to achieve a dough-like consistency. This process helps the pitch flow and thoroughly coat the coke particles, ensuring uniformity in the final product.

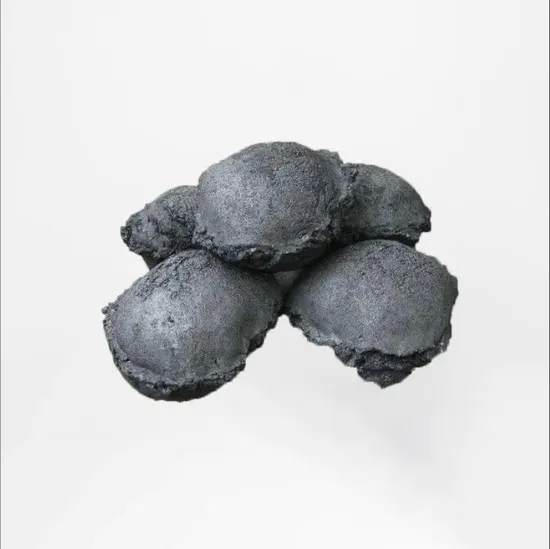

Forming the Paste: Once the mixture is well-blended and reaches the desired consistency, it is formed into paste or dough. The paste is then cooled and shaped into large blocks or used directly to coat electrode rods. In some cases, the paste may undergo additional processing steps like pressing or extrusion to achieve the correct texture and density.

Curing: Finally, the electrode paste is cured by allowing it to cool and solidify. The curing process enhances the paste's strength and makes it suitable for use in electric arc furnaces.

What Is Electrode Paste Used For?

Electrode paste is used in electric arc furnaces, especially in the production of ferroalloys and calcium carbide. It serves as a conductor of electricity and heat, allowing current to pass through the electrode into the furnace. Electrode paste is a mixture of calcined petroleum coke, coal tar pitch, and other additives.

It is fed into the top of self-baking electrodes, where it gradually bakes and hardens as it moves downward under high temperatures. This process forms a solid, conductive electrode. Electrode paste is essential for maintaining continuous operation and reducing energy loss in high-temperature industrial processes.