- Englist

Phone:

tel:+8615511858977

Email:

info@nalaibio.com

China Carbon Electrode Paste for Smelting Cylinder Trapezoid Oval Shape Briquette Carbon Electrode Paste

Product Description

Basic Info.

Shape

Plate

Usage

Electronic Equipment, High-Temperature Furnaces, Calcium Carbide Furnace

Sample

Support

MOQ

1ton

Transport Package

Standard Export Package

Specification

No. 2

Trademark

Nalai

Origin

China

HS Code

8506901000

Production Capacity

50000tons/Month

Product Description

Basic Info.

Product Description

Electrode paste has the characteristics of low resistivity and is used as a conductive material in electric furnace equipment such as ferroalloy furnace and calcium carbide furnace.

The consumption speed of the electrode and the calcination speed are the key to the use of the electrode paste. As the submerged arc furnace technology gradually develops toward large-scaled and air-tightness, during the calcining process, the heat obtained by the electrode from the furnace is greatly reduced, which requires an increase in the sintering perfromance of the electrode paste to compensate for this deficiency.

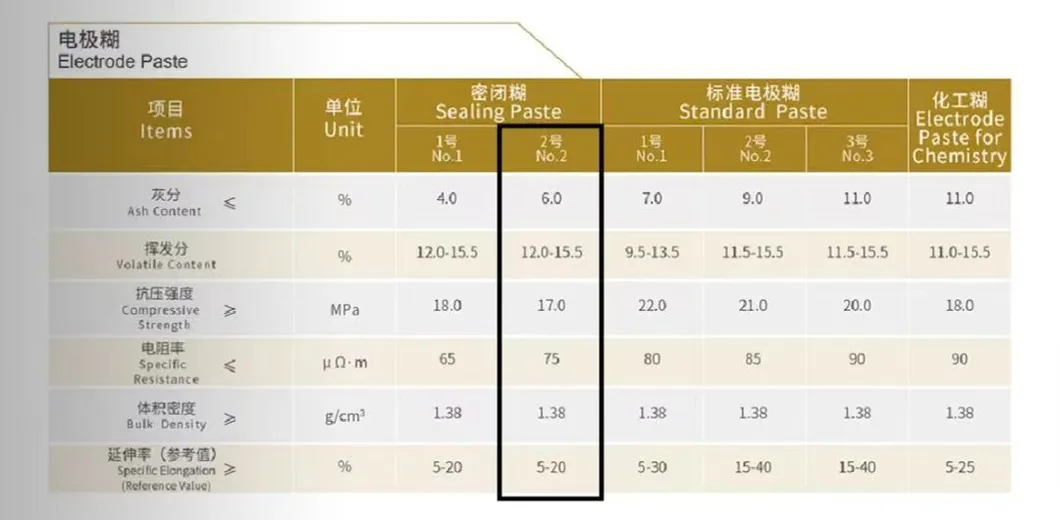

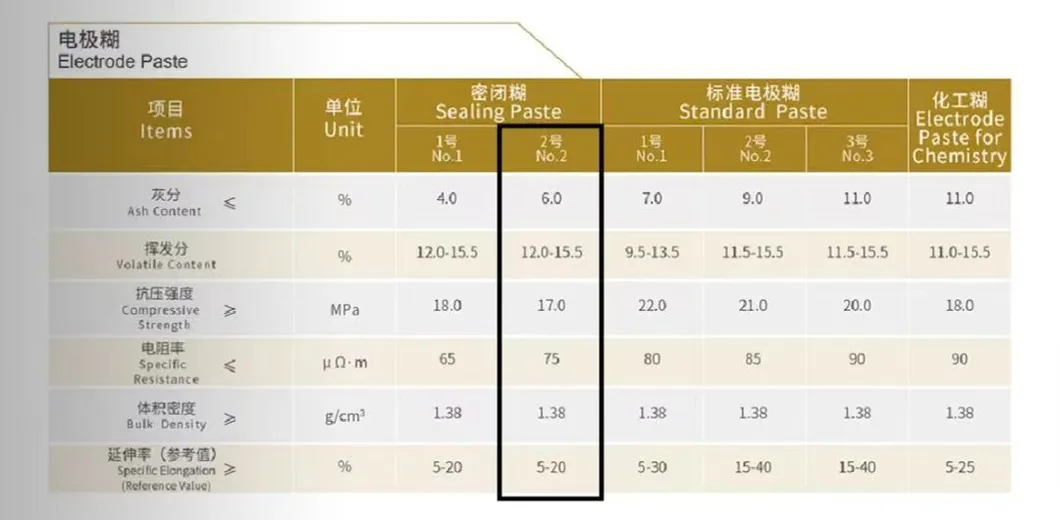

Type of Electrode Paste

Trapezoid Type Electrode Paste, Egg Type Electrode Paste, Cylinder Type Electrode Paste

Raw Materials of Electrodes Paste :

Electric Calcined Coal, Calcined Coal, Asphalt, Coal Tar,Anode Scrap, Graphite Powder, And Calcined Coke Powder.

Among them, electric calcined coal and calcined coal are the authentic Taixi coal from Ningxia

Packing&Shipping

Certificate

Company Profile

Shijiazhuang Nalai Biotechnology Co., Ltd Provide high quality Graphite electrode, Graphite electrode mainly petroleum

coke, needle coke as raw material, coal pitch as binder, calcination, ingredients, kneading, molding, baking and graphitization,

machining, made of, can be divided into ordinary power, high power and high power, mainly used in steel smelting electric arc furnace and refining furnace smelting furnace, electric furnace steelmaking is the use of graphite electrode in furnace to import

he current, strong current in the lower electrode by gas arc discharge, use the heat generated by the arc for smelting.Graphite electrodes of different diameters are used according to the capacity of the electric furnace. For continuous use of the electrodes, the electrodes are connected by the threaded joint of the electrodes. The graphite electrode used in steelmaking accounts for about 70 ~ 80% of the total graphite electrode consumption

If you need, please feel free to contact us. We will provide you with the most competitive price, high quality and excel service.,

etc

Factory & Workshop

Product Description

Electrode paste has the characteristics of low resistivity and is used as a conductive material in electric furnace equipment such as ferroalloy furnace and calcium carbide furnace.

The consumption speed of the electrode and the calcination speed are the key to the use of the electrode paste. As the submerged arc furnace technology gradually develops toward large-scaled and air-tightness, during the calcining process, the heat obtained by the electrode from the furnace is greatly reduced, which requires an increase in the sintering perfromance of the electrode paste to compensate for this deficiency.

Type of Electrode Paste

Trapezoid Type Electrode Paste, Egg Type Electrode Paste, Cylinder Type Electrode Paste

Raw Materials of Electrodes Paste :

Electric Calcined Coal, Calcined Coal, Asphalt, Coal Tar,Anode Scrap, Graphite Powder, And Calcined Coke Powder.

Among them, electric calcined coal and calcined coal are the authentic Taixi coal from Ningxia

Packing&Shipping

Certificate

Company Profile

Shijiazhuang Nalai Biotechnology Co., Ltd Provide high quality Graphite electrode, Graphite electrode mainly petroleum

coke, needle coke as raw material, coal pitch as binder, calcination, ingredients, kneading, molding, baking and graphitization,

machining, made of, can be divided into ordinary power, high power and high power, mainly used in steel smelting electric arc furnace and refining furnace smelting furnace, electric furnace steelmaking is the use of graphite electrode in furnace to import

he current, strong current in the lower electrode by gas arc discharge, use the heat generated by the arc for smelting.Graphite electrodes of different diameters are used according to the capacity of the electric furnace. For continuous use of the electrodes, the electrodes are connected by the threaded joint of the electrodes. The graphite electrode used in steelmaking accounts for about 70 ~ 80% of the total graphite electrode consumption

If you need, please feel free to contact us. We will provide you with the most competitive price, high quality and excel service.,

etc

Factory & Workshop

Carbon Electrode Paste FAQs

Can Carbon Electrode Paste be customized for different furnace conditions?

- Yes, the formulation can be adjusted in terms of binder type, volatile matter, ash content, and softening point to suit specific furnace temperatures, raw materials, and operational conditions.

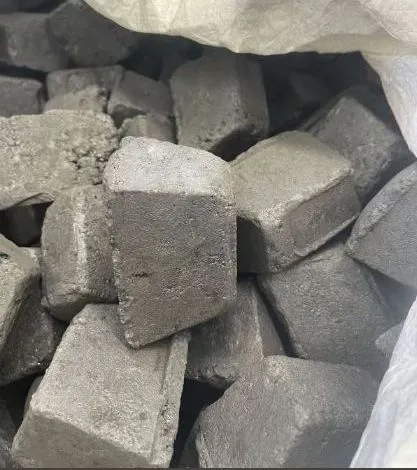

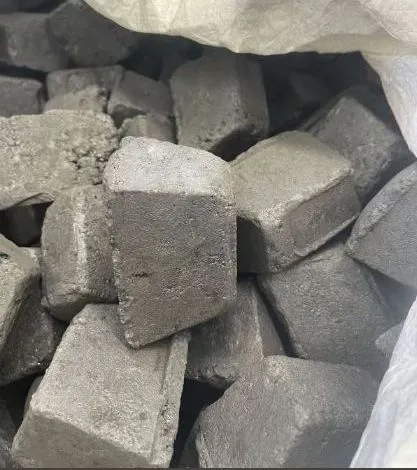

What forms does Carbon Electrode Paste come in?

- It is typically supplied in block or briquette form, but can also be provided in cylindrical or custom shapes for automated feeding systems.

Competitive price and high quality products, when we get your inquiry, we will come back to you at the first time.

Related Products

Related News

Powdered Graphite Lubricant Uses Revolution

The industrial world is buzzing about the remarkable versatility of powdered graphite lubricant uses that are transforming maintenance practices across industries.

Petroleum Coking Industry Market Analysis

The global energy sector continues to evolve with petroleum coking technologies playing an increasingly vital role in hydrocarbon processing.

Graphite Tube Innovations Revolution

The industrial world is buzzing with excitement about graphite tube technology that's transforming high-temperature applications.

Graphite Rod Revolution in Modern Industry

The industrial landscape is being transformed by the remarkable versatility of graphite rod technology, with applications spanning from aerospace to renewable energy.

Graphite Electrodes Revolutionizing Modern Industry

The industrial landscape is being transformed by the remarkable versatility of graphite electrodes, with applications spanning from steel production to advanced material processing.

Custom Graphite Plate Innovations

The industrial world is witnessing a quiet revolution with advanced custom graphite plate solutions transforming everything from semiconductor manufacturing to renewable energy systems.

Why Graphite Rods Are Used in Nuclear Reactors

Graphite bars and rods are essential components in high-tech industries like nuclear energy and aerospace due to their unique thermal and structural properties.

Thermal Management: How Graphite Plates Improve Heat Dissipation

Effective thermal management is crucial in industries ranging from electronics to aerospace, and graphite plates have emerged as a superior solution for heat dissipation.

Shijiazhuang nalai biotechnology Co., Ltd is a professional manufacturer in integrating design, development, trial and production. Our main products are graphite electrode, graphite rod, graphite block, graphite crucible., with 30 technicians and 360 skilled workers, and has a strict quality control system.

Products

Contact Us

Tel: 8615511858977

E-mail: info@nalaibio.com

Qiujingyiyuan,No.189,east2ndringnorthroad,chang'andistrict,shijiazhuang,hebeiprovince

Copyright © 2025 Shijiazhuang nalai biotechnology Co., Ltd All Rights Reserved. Sitemap | Privacy Policy

Lorem ipsum dolor sit amet, cons aring elit sed dllao the eimod tempor

inciunt ullaco laboris aliquip alora tempor inciunt temporin.Lorem ipsum dolor sit amet,Lorem ipsum

dolor sit amet, cons

aring elit

Social Media

Copyright © 2025 Shijiazhuang nalai biotechnology Co., Ltd All Rights Reserved. Sitemap | Privacy Policy

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.