- Englist

High Purity Recarburizer/Carburizing Agent for Steelmaking

High purity recarburizer, also known as carburizing agent, is a vital material used in steelmaking to adjust the carbon content of molten steel. It is a refined form of carbon, often derived from high-quality petroleum coke, coal, or other carbon-rich materials. The primary function of a recarburizer is to increase the carbon content of steel to the desired level during the refining process, particularly in electric arc furnaces (EAF) or induction furnaces.

The high purity of the recarburizer ensures minimal impurities in the final steel product, which is crucial for achieving the desired mechanical properties and quality. This material helps control the carbon level in steel, enhancing its hardness, strength, and wear resistance. It is commonly used in the production of high-quality steel grades such as stainless steel, tool steel, and alloy steel.

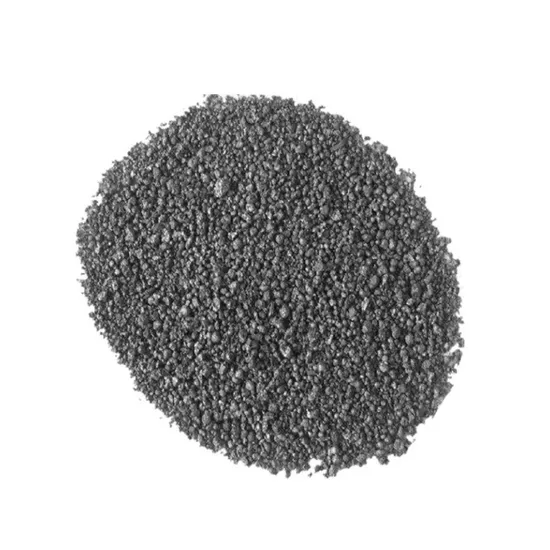

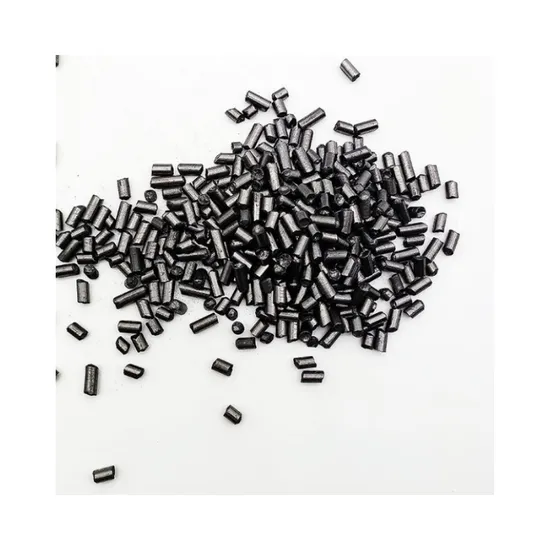

Recarburizers are available in different forms, such as granular, powder, or pellet, to suit various steelmaking processes. The use of high purity recarburizer ensures better control over the carbon content and reduces the need for additional alloying elements, improving the cost-effectiveness and consistency of the steel production process.

By accurately managing carbon levels, high purity recarburizers are essential in the production of steel with optimal properties for various industrial applications, such as construction, automotive, and machinery manufacturing.

High purity recarburizer, also known as carburizing agent, is a vital material used in steelmaking to adjust the carbon content of molten steel. It is a refined form of carbon, often derived from high-quality petroleum coke, coal, or other carbon-rich materials. The primary function of a recarburizer is to increase the carbon content of steel to the desired level during the refining process, particularly in electric arc furnaces (EAF) or induction furnaces.

The high purity of the recarburizer ensures minimal impurities in the final steel product, which is crucial for achieving the desired mechanical properties and quality. This material helps control the carbon level in steel, enhancing its hardness, strength, and wear resistance. It is commonly used in the production of high-quality steel grades such as stainless steel, tool steel, and alloy steel.

Recarburizers are available in different forms, such as granular, powder, or pellet, to suit various steelmaking processes. The use of high purity recarburizer ensures better control over the carbon content and reduces the need for additional alloying elements, improving the cost-effectiveness and consistency of the steel production process.

By accurately managing carbon levels, high purity recarburizers are essential in the production of steel with optimal properties for various industrial applications, such as construction, automotive, and machinery manufacturing.

High Purity Recarburizer FAQs

What is High Purity Recarburizer?

- High purity recarburizer is a carbon-rich material used in steelmaking to adjust and control the carbon content in molten steel. It is typically made from high-quality petroleum coke, coal, or other carbon-based materials and helps achieve the desired carbon level for specific steel grades.

How is High Purity Recarburizer applied in the steelmaking process?

- High purity recarburizer is typically added during the refining process in electric arc furnaces (EAF) or induction furnaces. It is introduced to the molten steel in granular, powder, or pellet form, depending on the specific process and carbon requirements.

Why is High Purity Recarburizer used in steelmaking?

- High purity recarburizer is essential for controlling the carbon content in steel. The right carbon level is crucial for achieving specific mechanical properties, such as strength, hardness, and wear resistance. It ensures high-quality steel production with minimal impurities, especially for high-performance steel grades.

What industries use High Purity Recarburizer?

- High purity recarburizer is widely used in industries where high-quality steel is required, such as in the production of stainless steel, tool steel, alloy steel, automotive components, construction materials, and machinery manufacturing. It is essential for producing steel with specific hardness, strength, and wear resistance properties.

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.