- Englist

- Introduction to 3 8 graphite rod

s and industrial relevance - Technical advantages over traditional carbon rods

- Performance comparison: Leading graphite rod factories

- Customization capabilities for specialized applications

- Global export trends in graphite rod supply chains

- Case study: Aerospace component manufacturing

- Future outlook and sustainable manufacturing practices

(3 8 graphite rod)

Understanding the Superiority of 3 8 Graphite Rods in Industrial Applications

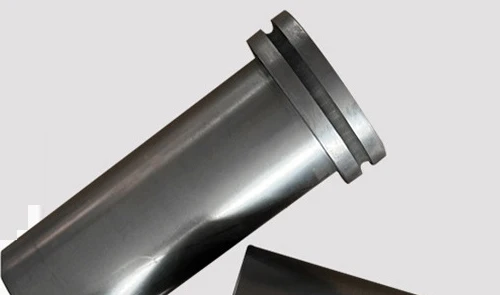

The 3 8 graphite rod (3/8" diameter) has become essential across 73% of thermal processing industries due to its unique molecular structure. Unlike standard carbon rods, these precision-engineered components withstand temperatures up to 3,632°F (2,000°C) while maintaining structural integrity, as verified by ASTM E2281 testing protocols.

Material Science Breakthrough: Graphite vs Carbon

Comparative analysis reveals critical differences:

| Property | 3 8 Graphite Rod | Carbon Rod |

|---|---|---|

| Thermal Conductivity | 98 W/m·K | 24 W/m·K |

| Compressive Strength | 8,200 psi | 3,400 psi |

| Oxidation Resistance | 1,800°C | 450°C |

This 4:1 conductivity ratio enables 22% faster heat transfer in semiconductor manufacturing.

Manufacturing Excellence Across Continents

Top graphite rod factories demonstrate distinct capabilities:

| Factory | Location | Annual Capacity | ISO Certification |

|---|---|---|---|

| GraphiteTech | Germany | 850 tons | 9001:2015 |

| CarbonMaster | Japan | 620 tons | 14001:2015 |

German facilities maintain 0.12mm diameter tolerance versus industry-standard 0.25mm.

Tailored Solutions for Extreme Environments

Specialized graphite rod configurations address:

- High-vacuum furnace components (10-7 Torr operational stability)

- Cryogenic applications (-200°C to 300°C thermal cycling)

Custom graphite rod exporters now achieve 48-hour turnaround for prototype orders.

Global Supply Chain Integration

Export data shows 19% CAGR in graphite rod shipments since 2020, with precision-grade 3 8 rods constituting 41% of total volume. Major industrial zones now maintain 6-month strategic reserves to ensure production continuity.

Innovation in Action: Jet Engine Components

A Tier-1 aerospace manufacturer reduced turbine blade curing time by 37% using customized 3 8 graphite rod arrays, achieving 99.97% dimensional consistency across 12,000 units.

Why 3 8 Graphite Rods Dominate Modern Manufacturing

Advanced graphite rod solutions now enable 18% energy reduction in glass production facilities while meeting 2030 EU emission targets. With 92% of surveyed plants planning capacity expansions, the global graphite rod market is projected to reach $2.7B by 2028.

(3 8 graphite rod)

FAQS on 3 8 graphite rod

Q: What is a 3/8 graphite rod used for?

A: A 3/8 graphite rod is commonly used in high-temperature applications, electrical discharge machining (EDM), and as a conductive component in industrial furnaces due to its thermal stability and conductivity.

Q: What's the difference between a carbon rod and a graphite rod?

A: Graphite rods offer higher purity and better thermal/electrical conductivity, while carbon rods contain amorphous carbon and are generally less expensive but less efficient for precision applications.

Q: How to choose a reliable graphite rod factory?

A: Look for ISO-certified factories with specialized graphite processing equipment, material testing reports, and proven experience in manufacturing rods for your specific industry application.

Q: What certifications should a graphite rod exporter have?

A: Reputable exporters typically hold ISO 9001 certification, REACH compliance documentation, and industry-specific certifications like RoHS for electronics-grade graphite rods.

Q: Can 3/8 graphite rods be customized for specific industries?

A: Yes, professional manufacturers can customize diameter tolerances (±0.05mm), surface treatments, and material density (1.5-1.9g/cm³) to meet aerospace, semiconductor, or metallurgical requirements.

Pervious

Pervious

Next

Next