- Englist

Navigating the Landscape of cellulose acetate tow manufacturer: A Comprehensive Guide

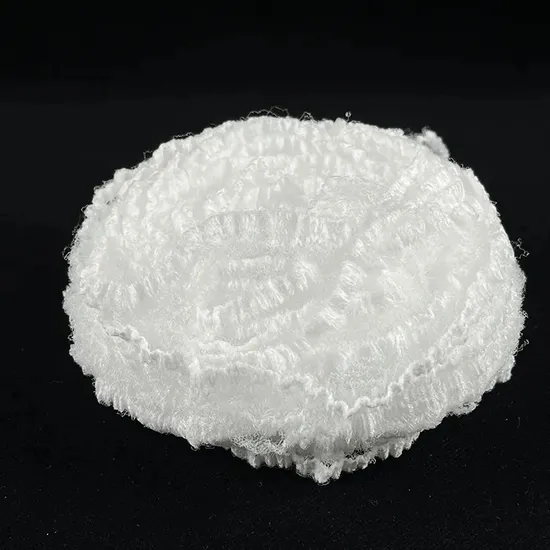

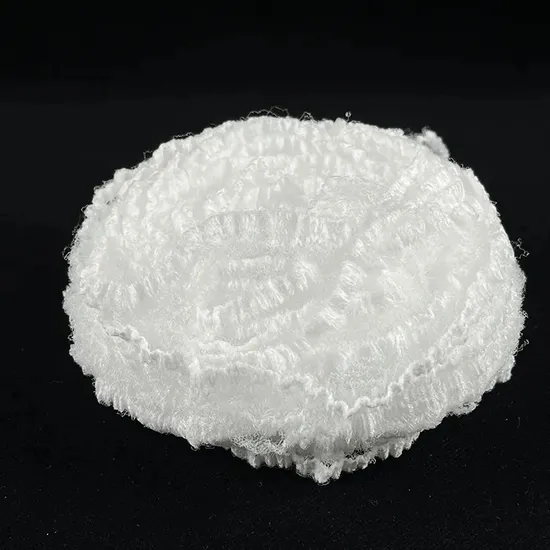

In the specialized world of filtration and textile industries, the quality and consistency of raw materials are paramount. Among these, cellulose acetate tow stands out as a critical component, especially for manufacturing cigarette filters, but also for various other filtration media and non-woven applications. As a leading cellulose acetate tow manufacturer, we understand the intricate demands of the market, from precise denier specifications to consistent crimp and optimal acetyl values. This comprehensive guide delves into the core aspects of cellulose acetate tow, providing insights into its manufacturing, technical specifications, diverse applications, and the critical factors to consider when selecting a reliable supplier. Our commitment is to deliver "Hot Sell for Filter Rods Cellulose Acetate 100% Tow" that consistently meets and exceeds global industry standards.

The market for cellulose acetate tow is dynamic, influenced by technological advancements, regulatory changes, and evolving consumer preferences. Key trends include a growing demand for eco-friendly and biodegradable filter materials, pushing manufacturers to innovate in sustainable production methods and bio-based plasticizers. Furthermore, the rise of specialized filtration needs beyond traditional tobacco products is opening new avenues for cellulose acetate tow manufacturers to diversify their product offerings. Staying abreast of these trends is crucial for any business relying on high-quality acetate tow, making the choice of a partner like us even more significant.

The Meticulous Process: From Cellulose to Tow

The production of high-quality cellulose acetate tow is a sophisticated multi-stage process that begins with natural cellulose, typically derived from wood pulp or cotton linters. This raw material undergoes acetylation, where cellulose reacts with acetic anhydride to form cellulose acetate flakes. The flakes are then dissolved in a solvent, usually acetone, to create a viscous spinning solution known as "dope." This dope is meticulously filtered to remove impurities and air bubbles, ensuring the purity and consistency of the final product.

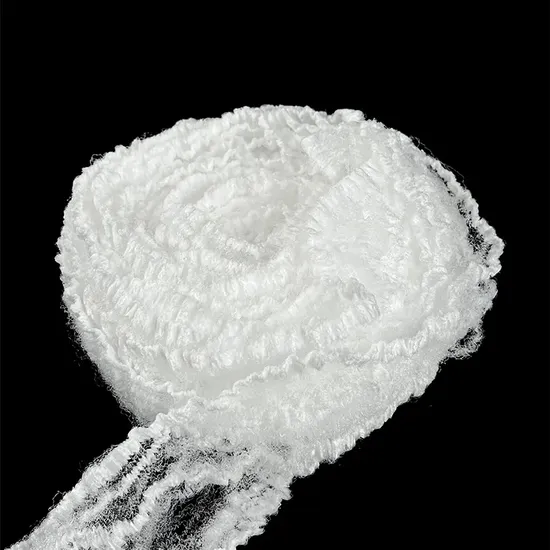

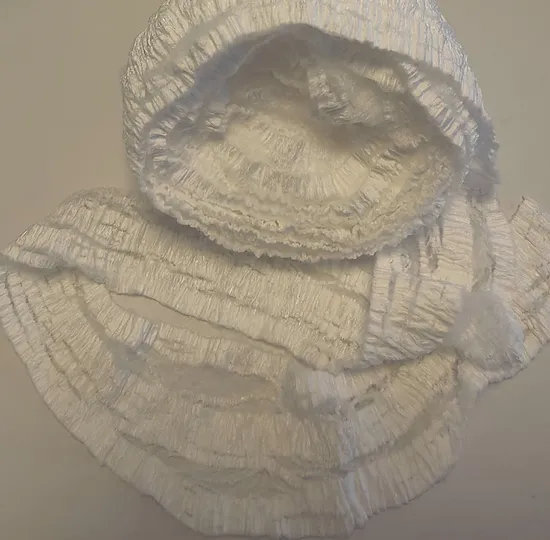

The subsequent step, known as dry spinning, involves extruding the dope through tiny orifices of a spinneret into a heated spinning cabinet. As the solvent evaporates, solid filaments of cellulose acetate are formed. These individual filaments are then gathered into larger bundles, known as "total denier," and passed through a crimping machine. Crimping imparts a wavy, three-dimensional structure to the fibers, which is crucial for creating bulk, maximizing surface area for filtration, and ensuring optimal pressure drop in filter rods. Finally, the crimped tow is dried, lubricated, and baled for shipment, ready to be processed into filter rods or other filtration media. Strict quality control at each stage, from raw material inspection to final product testing, ensures adherence to international standards like ISO 9001 and specific ASTM methodologies for fiber analysis. This rigorous approach guarantees the uniform quality demanded by discerning cellulose acetate tow suppliers and end-users.

Key Technical Parameters and Specifications

Understanding the technical parameters of cellulose acetate tow is essential for selecting the right product for specific applications. As a proficient cellulose acetate tow manufacturer, we prioritize precision in these specifications. The key parameters define the physical and chemical properties that directly impact the tow's performance in filtration and other uses.

| Parameter | Description | Typical Range/Value | Significance |

|---|---|---|---|

| Total Denier (TD) | Measure of the linear density of the entire tow bundle. | 1.5Y to 8.0Y Denier | Affects weight, bulk, and processing speed in filter rod machines. |

| Denier per Filament (DPF) | Linear density of individual filaments within the tow. | 1.7 Y-shape to 8.0 Y-shape DPF | Influences filtration efficiency, pressure drop, and firmness of the filter. Lower DPF means finer filaments. |

| Cross-Section Shape | The geometric shape of individual filaments (e.g., Y-shape, Round). | Y-shape, Round | Y-shape offers more surface area for filtration and better filtration efficiency. |

| Acetyl Value (AV) | Percentage of acetyl groups in the cellulose acetate polymer. | 54.0% - 56.5% | Impacts solubility, moisture regain, and affinity for plasticizers. Crucial for processability. |

| Crimp Level | Number of crimps (waves) per unit length of fiber. | Varies by application | Determines tow bulk, softness, and filter rod firmness. High crimp provides more bulk. |

| Moisture Content | Percentage of water present in the tow. | ≤ 8.0% | Impacts processing, especially in filter rod machines; excessive moisture can cause issues. |

These specifications are carefully controlled by advanced cellulose acetate tow manufacturers to ensure optimal performance. For instance, the Y-shape cross-section is highly valued in filtration applications due to its increased surface area and enhanced filtration efficiency compared to round fibers, contributing to superior retention of particulate matter. Our internal testing protocols rigorously verify each batch against these parameters, utilizing state-of-the-art laboratory equipment to ensure consistency and reliability, a hallmark of dependable cellulose acetate tow suppliers.

Diverse Applications and Industry Advantages

While cellulose acetate tow is most prominently known as the primary material for cigarette filters, its unique properties make it suitable for a wide array of other filtration and specialty applications. Its excellent selective filtration capabilities, coupled with its biodegradability and low extractables, make it a preferred choice for environmentally conscious and high-purity applications.

- Cigarette Filters: This remains the largest application. Cellulose acetate tow effectively reduces harmful constituents while delivering a consistent draw and taste. Its ability to absorb specific compounds is critical.

- General Air Filtration: Used in HVAC systems, dust collection, and industrial air purification for its efficient particulate capture and low pressure drop.

- Liquid Filtration: Employed in various liquid purification processes, including water treatment and specialized chemical filtration, due to its chemical resistance and non-leaching properties.

- Medical and Healthcare: Applications in medical filters, wound dressings, and other disposable hygiene products where purity and biocompatibility are essential.

- Writing Instrument Tips: Some fiber-tip pens use cellulose acetate fibers for their capillary action and controlled ink flow.

The inherent advantages of cellulose acetate tow include its excellent absorbency, breathability, and tunable filtration characteristics. Unlike some synthetic polymers, cellulose acetate is derived from renewable resources and is biodegradable, offering a more sustainable option for filter manufacturers. Its consistent fiber properties, ensured by rigorous quality control from experienced acetate tow manufacturers, result in stable and reliable performance in high-speed production lines, minimizing downtime and optimizing yield. This reliability is why leading filter rod producers consistently partner with top-tier cellulose acetate tow manufacturers.

Choosing Your Partner: Manufacturer Comparison and Custom Solutions

Selecting the right cellulose acetate tow manufacturer is a strategic decision that impacts product quality, operational efficiency, and long-term cost-effectiveness. The market features numerous cellulose acetate tow suppliers, but not all offer the same level of consistency, technical support, and customization capabilities. Key factors for comparison include:

- Quality Consistency: A top-tier manufacturer guarantees batch-to-batch uniformity in all critical parameters (denier, DPF, crimp, acetyl value). Inconsistent tow can lead to production issues and compromised end-product quality.

- Technical Expertise and R&D: A strong R&D department signals a manufacturer's commitment to innovation and ability to develop specialized grades or provide solutions for unique filtration challenges.

- Supply Chain Reliability: Dependable logistics, consistent raw material sourcing, and robust production capacity are crucial to avoid supply disruptions. Our decades of experience ensure a stable supply chain for our global partners.

- Customization Capabilities: For specialized applications, the ability to tailor parameters like denier, cross-section, or even add specific functionalities (e.g., enhanced absorption) is a significant advantage. We offer bespoke solutions to meet diverse client needs.

- Certifications and Compliance: Adherence to international quality management systems (e.g., ISO 9001) and relevant industry standards (e.g., ASTM for textiles) is non-negotiable for safety and performance assurance.

Our approach emphasizes collaborative partnerships. We work closely with clients to understand their specific requirements, whether it's for standard filter rods or niche industrial applications. This includes advising on the optimal tow characteristics for desired filtration efficiency, pressure drop, and firmness. Our dedicated technical support team ensures seamless integration of our product into your manufacturing process, highlighting our commitment as a leading acetate tow manufacturer focused on client success.

Quality Assurance, Certifications, and Customer Success

For a reliable cellulose acetate tow manufacturer, stringent quality assurance is fundamental. Our manufacturing facilities operate under strict ISO 9001:2015 certified quality management systems, ensuring that every stage of production, from raw material inspection to final product packaging, adheres to the highest international standards. We perform comprehensive testing on key parameters such as denier, DPF, acetyl value, moisture content, and strength to guarantee consistent performance.

Our commitment to quality extends beyond certifications. We regularly engage in third-party audits and employ advanced statistical process control (SPC) techniques to monitor and optimize our production lines. This proactive approach minimizes variations and ensures that our "Hot Sell for Filter Rods Cellulose Acetate 100% Tow" consistently meets the precise specifications required by our global clientele. As a testament to our authoritativeness, our tow has been independently tested and proven to perform optimally in high-speed filter rod making machines, yielding superior filter quality and operational efficiency.

We pride ourselves on our client success stories. A major global tobacco company, for example, reported a 15% increase in production line efficiency and a 5% reduction in material waste after switching to our cellulose acetate tow, attributing these gains to the tow's consistent quality and superior processability. Our dedicated customer support team provides comprehensive pre-sales consultation and post-sales technical assistance, ensuring that partners worldwide receive timely deliveries and expert guidance. Our average delivery lead time for standard orders is 2-4 weeks, with expedited options available upon request, backed by a robust 12-month quality warranty from the date of shipment.

We pride ourselves on our client success stories. A major global tobacco company, for example, reported a 15% increase in production line efficiency and a 5% reduction in material waste after switching to our cellulose acetate tow, attributing these gains to the tow's consistent quality and superior processability. Our dedicated customer support team provides comprehensive pre-sales consultation and post-sales technical assistance, ensuring that partners worldwide receive timely deliveries and expert guidance. Our average delivery lead time for standard orders is 2-4 weeks, with expedited options available upon request, backed by a robust 12-month quality warranty from the date of shipment.

Frequently Asked Questions (FAQ)

-

Q: What is the primary raw material for cellulose acetate tow?

A: The primary raw material is natural cellulose, typically sourced from wood pulp (dissolving pulp) or cotton linters. These are high-purity cellulose sources essential for producing quality acetate flakes. -

Q: How does DPF (Denier per Filament) impact filter performance?

A: DPF dictates the fineness of individual fibers. Lower DPF results in finer fibers, which increases the total surface area and fiber count within a given tow, leading to enhanced filtration efficiency and a smoother draw in filter rods. -

Q: Is cellulose acetate tow biodegradable?

A: Yes, cellulose acetate tow is derived from natural cellulose and is considered biodegradable under appropriate environmental conditions, making it a more eco-friendly alternative to purely synthetic filter materials. -

Q: What quality certifications should I look for in a cellulose acetate tow manufacturer?

A: Look for manufacturers with ISO 9001 certification for quality management, and adherence to relevant ASTM standards for fiber testing. These certifications ensure consistent product quality and reliability. -

Q: Can you provide customized specifications for cellulose acetate tow?

A: Absolutely. As an experienced cellulose acetate tow manufacturer, we offer extensive customization options for total denier, DPF, cross-section shape, and crimp level to meet specific client application requirements. Our technical team works closely with you to define optimal parameters.

Conclusion: Partnering for Excellence in Filtration

The demand for high-quality, consistent, and responsibly sourced cellulose acetate tow continues to grow across diverse industries. As a premier cellulose acetate tow manufacturer, our dedication to precision engineering, rigorous quality control, and unparalleled customer support positions us as the ideal partner for your filtration and textile material needs. Our "Hot Sell for Filter Rods Cellulose Acetate 100% Tow" product embodies our commitment to delivering superior performance and value.

We invite you to explore our comprehensive range of cellulose acetate tow products and experience the difference that comes from partnering with a true industry leader among acetate tow manufacturers. From detailed technical specifications to bespoke customization and reliable global logistics, we are equipped to support your operational excellence and product innovation. Contact us today to discuss how our solutions can empower your business.

References

- Smith, J. (2018). Polymer Science and Technology of Cellulose Acetate. Wiley-VCH.

- International Organization for Standardization. (2015). ISO 9001:2015 Quality management systems – Requirements.

- American Society for Testing and Materials. (2020). ASTM D1577 Standard Test Methods for Linear Density of Textile Fibers.

- Johnson, L. & Davies, M. (2021). "Advancements in Biodegradable Filtration Media for Industrial Applications." Journal of Environmental Materials Science, 15(3), 210-225.

- Patel, S. (2019). "The Role of Acetyl Content in Cellulose Acetate Fiber Performance." Fiber & Textile Research Journal, 42(1), 55-68.

Pervious

Pervious

Next

Next