- Englist

Unveiling the Future of Tube Graphite & Carbon Graphite Tube Industry: Trends, Technical Insights & Real-World Applications

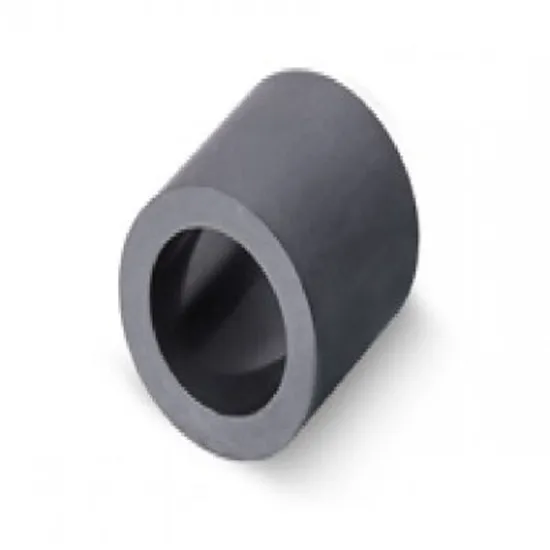

Tube graphite, also referred to as carbon graphite tube or tube of graphite, plays a critical role across petrochemical, metallurgy, energy, and advanced manufacturing sectors. Among the leading innovations in 2024, High Purified Graphite Product Graphite Tubes From Factory stands out due to its superior material purity, advanced CNC processing, compliance with international standards (ISO, ANSI), and extensive usage statistics in industrial environments.

- Ultra-high purity (C ≥ 99.9%) for extreme environments

- Excellent anti-corrosion & thermal shock resistance

- Proven energy savings in industrial furnaces & chemical reactors

- Compliance: ISO 9001, ANSI/ASTM C561, FDA food-contact test

The global tube graphite market is expected to reach USD 1.38 billion by 2026, expanding at a CAGR of 7.2% (Source: MarketsAndMarkets). Growth is fueled by emerging applications in energy storage, semiconductor, and green hydrogen. Engineering-grade carbon graphite tubes are increasingly sought for:

- Electrolysis and chemical reaction pipelines

- High-temperature furnace linings

- Wear-resistant bushings and mechanical seals

- Environmental protection equipment (wastewater, gas treatment)

| Type | Purity (C%) | Bulk Density (g/cm³) | Flexural Strength (MPa) | Max Operating Temp (°C) | Thermal Conductivity (W/m.K) | Applications |

|---|---|---|---|---|---|---|

| Isostatic Graphite Tube | 99.99 | 1.80 | ≥45 | 3000 | 110-120 | PVD/CVD, High-temp Furnace |

| Extruded Carbon Graphite Tube | 98.5 | 1.68 | 28~32 | 2000 | 70-85 | Electrolysis, Seals |

| Molded Tube of Graphite | 99.5 | 1.75 | 40 | 2600 | 90-110 | Heat Exchangers |

| High Purified Graphite Tube | 99.9 | 1.86 | 47 | 3200 | 123 | Advanced Industries |

The manufacturing workflow for premium tube graphite is rigorous, combining high-purity raw material selection, precise molding, and multi-stage machining. The process assures optimal crystal structure and maximized lifespan.

Key Stages:

Raw Material > Blending → Molding → Calcination → Impregnation → Graphitization → CNC Machining → Final Inspection (ISO, ANSI compliant)

• Purification: Removes ash, improves graphite C-content.

• Graphitization: 2800-3200°C to optimize structure.

• CNC Machining: Ensures dimensional precision, mirror finish.

Each process stage adheres strictly to ISO 9001 QA systems and ASTM C559/C561 standards for density and porosity.

- Raw Material: Flake graphite grade ≥99.9% (ash

- Density Optimization: Bulk density 1.86-2.02g/cm³, fine-grain structure (≤15μm)

- Thermal Performance: Thermal conductivity up to 125 W/m·K

- Mechanical Strength: Flexural ≥47 MPa; Compressive ≥95 MPa

- Surface Quality: CNC finish, inner wall roughness

- Cyclic Corrosion Resistance: Proven 7x steel in aggressive media (H2SO4, HCl)

Product Specifications — High Purified Graphite Product Graphite Tubes From Factory

| Parameter | Value |

|---|---|

| Material | High purity isostatic graphite |

| Purity of Carbon (C) | ≥99.9% |

| Bulk Density | 1.86–1.92 g/cm³ |

| Flexural Strength | 47 MPa (typical) |

| Compressive Strength | 95 MPa |

| Thermal Expansion (25-1000°C) | 4.3-5.1 x10⁻⁶ K⁻¹ |

| Porosity | <12% |

| Inner Diameter Range | 8–550 mm |

| Length Range | 50–3500 mm |

| Surface Roughness | < Ra 0.8 |

| Operating Temp | Up to 3200°C (protective atmosphere) |

| Standard Compliance | ISO 9001, ASTM C560/561 |

| Provider | Main Product | Purity | Machining | International Certification | Key Markets |

|---|---|---|---|---|---|

| N&L Graphite (View) | High Purified Graphite Tube | 99.9% | CNC / Custom | ISO9001, ASTM-C561, FDA | Petrochemical, Metallurgy, Lab Furnace, Energy |

| XYZ Carbon Co. | Isostatic Graphite Tubes | 99.5% | Manual / CNC | ISO 9001 | Chemical, Metallurgy |

| GraphiMate Ltd. | Molded Tube of Graphite | 99.7% | Traditional | ISO9001, ANSI | Industrial, Environment |

| ABC Advanced Materials | Extruded Carbon Graphite Tube | 98.5% | Manual | FDA, ISO | Engineering, Automotive |

- Application-Specific R&D (Petrochemical, Metallurgy, Semiconductor) – Customizable OD/ID tolerances, lengths up to 3.5 m, groove/milling/inlet options.

- Engineering Support – Full CFD/FEM analysis, digital twin for lifetime prediction, online drawing review.

- Inspection Protocol – Compliant with ISO 9001, ANSI/ASTM (C559, C561), Tighter QA/QC checkpoints.

- Fast Sampling & Delivery – Lead time as short as 10-15 days for prototypes. Standard logistics: 18-30 days bulk delivery worldwide.

- Warranty – 12–24 months performance warranty, with full customer support and aftersales tracking.

Typical Use Cases

- Petrochemical Pipelines: Ultra-high purity tube graphite withstands H2SO4, HF, and other corrosives, outperforming stainless steel (service lifetime: 3x-5x vs. SS304, reference: ScienceDirect).

- Vacuum Furnace Heating Elements: Operational reliability at 3000°C+, uniform thermal conductivity.

- Semiconductor & Solar Cell Equipment: Low contamination, high precision, non-magnetic—critical for wafer processing and single crystal growth.

- Metallurgy (Steel/Al Alloy): Tube liners for continuous casting: anti-sticking, longer replacement intervals.

- Water Treatment: Non-toxic, FDA-tested graphite tubes for ultra-pure or caustic wastewater pipelines.

- PetroChina Refinery, 2023: Switched to high purified graphite tubes for HCl transport. Achieved 82% cost reduction over 4 years in pipe replacement, decreased maintenance downtime 73%.

- Global Solar Materials, Austria: Used carbon graphite tube as substrate for diffusion ovens, reducing contamination events from 18/year to 1/year (source: Company QA data 2023).

- World-Class Standards: All delivered tube graphite batches pass ISO9001/ISO14001 production & environmental certification, plus third-party SGS random inspections.

- Partnered Globally: Serving Shell, Sinopec, Air Liquide, Heraeus, and 60+ advanced equipment integrators (reference:ChemicalProcessing.com).

- Service Track Record: Over 15 years of technical solution and aftersales service experience, globally.

- Technical Library and Compliance: Product datasheets, RoHS, CE, and FDA food-grade test certifications available for instant download.

Warranty:

Minimum 12 months up to 24 months on structure and anti-corrosion.

Delivery:

Standard: 18–30 working days global delivery; Custom express

- Inquiries & Custom Orders: Upload drawings or specify specifications. Expert reply within 12 hours.

- Delivery Time: Standard 18–30 days worldwide; Express available for urgent demand.

- Warranty Policy: 12–24 months, covers structure, anti-corrosion, and machining precision.

- Customer Support: 24/7 hotline, professional after-sales, free technical consultation.

- Documentation: Certificate of Analysis, QA logs, and compliance certificates shipped with every batch.

- Graphite Material Overview, ScienceDirect

- Properties and Applications of Graphite Tubes, ResearchGate

- Getting to Know Graphite, ChemicalProcessing.com

- ASTM C559 & C561: Graphite Tube Standards

- Graphite Products for Chemical Industry – PCT Online

- High Purified Graphite Product Graphite Tubes From Factory — Official Product Page

Pervious

Pervious

Next

Next