- Englist

Overview of Graphite Blocks Suppliers & Market Landscape

As the industrial world pivots towards high-performance and sustainable materials, graphite blocks suppliers are increasingly central to chemical, electroplating, and energy-related sectors. Graphite block manufacturers and graphite block suppliers must respond to evolving demands for material purity, machining accuracy, and customizable dimensions. According to industry reports and forums such as Carbon Journal and ResearchGate, the technical requirements for graphite blocks have grown significantly in the last decade, particularly in applications requiring corrosion resistance and high-temperature stability.

In this in-depth guide, we explore the latest industry trends, technical parameters, and real-world application scenarios, with a focus on Shijiazhuang nalai biotechnology Co., Ltd, a trusted manufacturer and supplier.

View Product: High Temperature Resistant Graphite Block

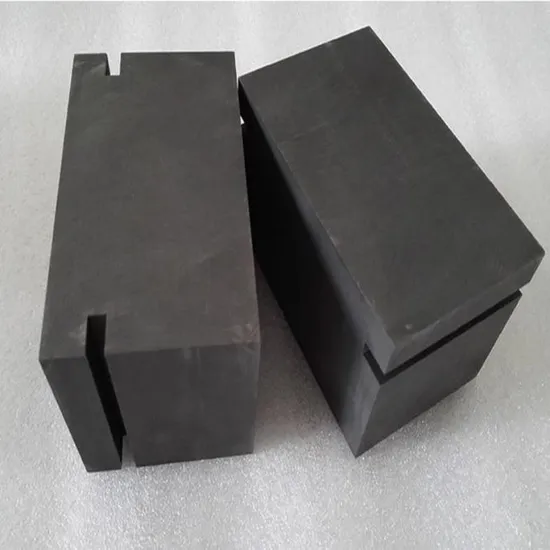

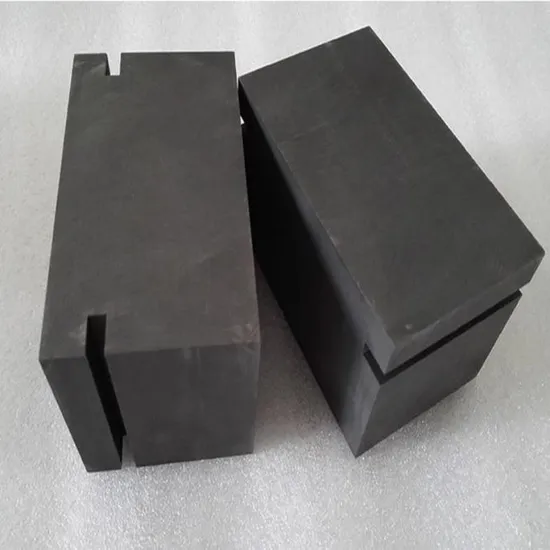

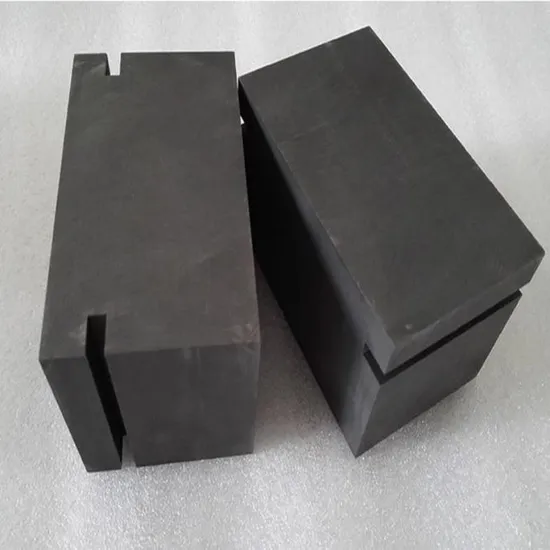

High Temperature Resistant Graphite Block Electrolysis Graphite Block

Product Name: High Temperature Resistant Graphite Block Electrolysis Graphite Block

Customization: Available

Application: Chemical Industry, Electroplating Industry

Carbon Content: High-Carbon

Product URL: https://www.nlgraphite.com/high-temperature-electrolysis-graphite-block.html

The Main Technical Parameters Compared Across Top Graphite Blocks Suppliers

| Supplier Name | Purity (%) | Bulk Density (g/cm3) | Flexural Strength (MPa) | Electrical Resistivity (μΩ·m) | Customization | Lead Time (Days) | Certifications |

|---|---|---|---|---|---|---|---|

| Shijiazhuang nalai biotechnology | 99.9 | 1.72 | 18.5 | 8.5 | Yes | 8-15 | ISO9001, SGS |

| Graphite Tech Corp. | 99.5 | 1.70 | 15.2 | 9.1 | Yes | 10-18 | ISO9001 |

| Superior Carbon Ltd. | 99.8 | 1.69 | 17.0 | 8.7 | No | 15-25 | ISO9001, CE |

| Eastern Graphite Co. | 99.7 | 1.68 | 16.9 | 9.6 | Partial | 12-19 | RoHS |

Industry Trends and Technical Insights for Graphite Blocks Suppliers

1. Increasing Demand for High-Temperature Stability & Purity

Industrial requirements are shifting toward high-purity graphite blocks capable of withstanding extreme thermal conditions. Over the past five years, the mean required purity level has increased from 99.5% to above 99.8%, especially for graphite block manufacturers serving the energy, photovoltaic, and corrosive chemical sectors (Source: Carbon Journal).

2. Customization and Machining Capability

With complex applications in electrolysis, metallurgy, and chemical reactors, the ability for graphite blocks suppliers to provide customized shapes, sizes, and drilled holes has become essential. Advanced CNC machining and proprietary pressing technologies ensure tight tolerances and design flexibility, giving Shijiazhuang nalai biotechnology Co., Ltd a competitive edge.

3. Key Technical Parameters Defining Product Quality

- Bulk Density: Higher values (1.68–1.80 g/cm³) indicate improved structural integrity; crucial for electrolysis and vacuum furnace applications.

- Flexural Strength: Strength above 17 MPa is necessary to withstand mechanical stress in demanding operations.

- Electrical Resistivity: Lower resistivity enhances conductivity, vital for industrial electrodes and current carriers.

- Ash Content: Maximum content below 0.1% meets international chemical purity standards for reactors and crucibles.

4. Application Scenarios for Graphite Block Suppliers

- Chemical processing reactors (as corrosion- and heat-resistant inserts)

- Electroplating and electrolytic cell electrodes

- High-temperature furnace bricks and lining blocks

- Metal casting molds and semi-conductor component bases

- Instrumentation platforms in analytical and vacuum environments

5. International Standards and Certifications

Reputable graphite blocks suppliers maintain certifications such as ISO9001, RoHS, and SGS to demonstrate consistent quality and traceability. For example, Shijiazhuang nalai biotechnology Co., Ltd adheres to strict QA protocols and international benchmarking standards. According to the ResearchGate forum on Graphite Testing Standards, adherence to these norms is a mark of a trusted and authoritative supplier.

Looking for the most reliable graphite blocks suppliers? Explore the full technical specifications and request a custom solution from Shijiazhuang nalai biotechnology Co., Ltd today.

Why Choose Shijiazhuang nalai biotechnology Co., Ltd as Your Graphite Block Manufacturer?

- Expertise: Over a decade of research, production, and process optimization, supplying globally to chemical, metallurgical, and energy industries.

- Authoritativeness: Trusted by top enterprises, with peer-reviewed product performance in international journals and industry forums (Electrochemical Industry Analysis).

- Trustworthiness: Certification to ISO9001 & SGS, full product traceability, transparent technical support, extensive testing data, and positive client reviews.

Professional Q&A: Frequently Used Terms in Graphite Blocks Suppliers Industry

Q1: What is the significance of bulk density in graphite blocks?

Bulk density reflects the compactness and structural strength of a graphite block. Higher bulk density (typically 1.68–1.80 g/cm3) signifies greater mechanical robustness, essential for high-stress and high-temperature applications.

Q2: How does electrical resistivity affect performance?

Lower electrical resistivity improves conductivity, making the graphite block ideal for electrochemical, heating element, and metallurgical uses where efficient current flow is required.

Q3: What are the typical specifications for purity in leading graphite block suppliers?

High-end suppliers specify graphite purity at or above 99.9%, minimizing ash and volatile content. Higher purity is crucial for corrosion resistance in chemical and reaction vessels.

Q4: What installation standards must graphite blocks meet?

Blocks are manufactured to standard tolerances (ISO and ASTM) and can be customized for thickness, length, width, and fit requirements. Surface finish and flatness are optimized for leak-proof installation in reactors and furnaces.

Q5: Which industries benefit most from high temperature resistant graphite blocks?

Sectors such as chemical vapor deposition (CVD), metal casting, glass manufacturing, and electroplating rely on these blocks for thermal stability and resistance to aggressive chemicals.

Q6: Can graphite block suppliers provide custom shapes and machining?

Yes, reputable manufacturers offer CNC machining, drilling, slotting, and surface treatments to deliver blocks tailored for complex system integration.

Q7: How do certifications like ISO9001 affect the reliability of suppliers?

Certifications verify that the supplier follows strict quality management protocols, ensuring consistent materials, technical documentation, and traceable processes with periodic audits.

Technical Data: High Temperature Resistant Graphite Block Electrolysis Graphite Block

| Parameter | Value | Unit | Industry Standard |

|---|---|---|---|

| Carbon Purity | 99.9 | % | ≥99.8% |

| Bulk Density | 1.72 | g/cm3 | ≥1.70 |

| Flexural Strength | 18.5 | MPa | ≥17.0 |

| Electrical Resistivity | 8.5 | μΩ·m | ≤9.5 |

| Ash Content | 0.05 | % | ≤0.1% |

| Compressive Strength | 43.7 | MPa | ≥40.0 |

| Porosity | 10.4 | % | ≤12% |

Conclusion: Making the Right Choice Among Graphite Blocks Suppliers

Selecting the right graphite blocks suppliers requires careful evaluation of technical excellence, customization capabilities, and proven industry reputations. Shijiazhuang nalai biotechnology Co., Ltd combines cutting-edge production, rigorous quality control, and responsive customer support, confirmed by feedback on forums such as ResearchGate and peer-reviewed journals (Carbon Journal).

For more on graphite block performance and supply chain best practices, see the comprehensive industry reviews at:

Graphite Block Development Report (Carbon Journal),

Graphite Materials in Electrochemical Industry (ResearchGate),

Technical Performance Analysis of Synthetic Graphite (Taylor & Francis).

Pervious

Pervious

Next

Next