- Englist

Phone:

tel:+8615511858977

Email:

info@nalaibio.com

In today’s competitive metallurgical market, HP graphite electrodes have become fundamental consumables, especially in EAF (Electric Arc Furnace) steelmaking. This article delivers an in-depth analysis of HP graphite, benchmarking against carbon graphite electrode and eaf graphite electrodes, encompassing industry trends, technical specifications, manufacturing flow, use cases, international standards, and custom solutions.

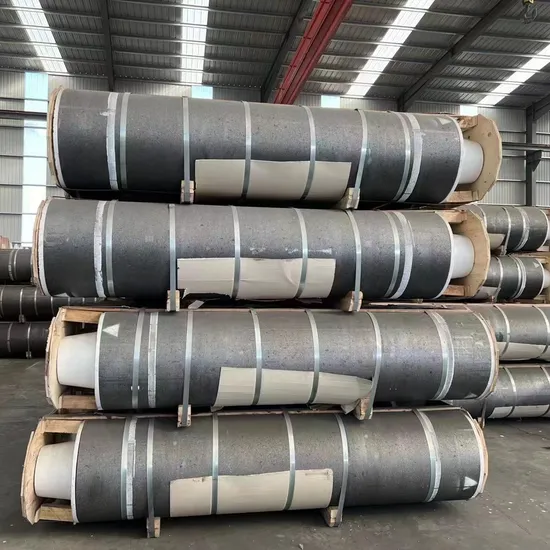

Product Spotlight: Hot Sale HP Graphite Electrode Good Quality UHP Graphite Electrode

Product Spotlight: Hot Sale HP Graphite Electrode Good Quality UHP Graphite Electrode

1. Industry Trends: The Pre-eminence and Market Growth of HP Graphite

According to Roskill’s 2023 report[1], the worldwide demand for HP graphite electrodes has grown at a CAGR of 5.8% from 2016–2023, driven by high-output EAF steelmaking and non-ferrous metal industries. The global graphite electrode market size reached $8.42 billion in 2023 and is projected to surpass $11.6 billion by 2028.

- Primary downstream sectors: EAF metallurgy, foundry, ferroalloy, silicon metal, petrochemical industry, wastewater treatment.

- Technical evolution: Increased electrode density and resistance to arc erosion, meeting higher power demands in modern furnaces.

HP Graphite Electrode Market Applications, 2023

| Application Area | Market Share (%) | Key Requirements |

|---|---|---|

| EAF Steelmaking | 53.2 | High current, abrasion/corrosion resistance, longevity |

| Foundry & Alloy | 18.4 | Purity, high thermal stability |

| Chemical & Petrochemical | 15.7 | Strong anti-oxidation, acidic/alkaline corrosion |

| Others (Silicon, Water-treat, etc.) | 12.7 | Custom diameters/types |

2. Technical Specifications & Data Sheet for HP Graphite

Below is a summarized technical comparison table for standard hp graphite, carbon graphite electrode, and UHP electrodes. Data is industry-sourced and aligns with ISO 9001:2015 and ANSI/ASTM C1179-18 standards.

Electrode Parameter Table [ASTM C1179-18]

| Parameter | HP Graphite | Carbon Graphite Electrode | UHP Graphite Electrode | Testing Standard |

|---|---|---|---|---|

| Bulk Density (g/cm³) | 1.68–1.72 | 1.58–1.62 | 1.72–1.78 | ISO 8007-2 |

| Resistivity (μΩ·m) | 5.0–6.5 | 6.5–8.0 | 4.2–5.0 | ASTM C1179-18 |

| Flexural Strength (MPa) | 9.8–12.0 | 7.5–9.5 | 12.5–17.0 | ISO 1209 |

| Ash Content (%) | < 0.3 | 0.5–1.0 | < 0.3 | ISO 8007-1 |

| Operating Current (A/cm²) | 18–25 | 10–14 | 25–32 | IEC 60672 |

| Recommended Furnace Power (MVA) | 40–80 | 25–40 | 80–150 | N/A |

| Service Life (Cycles) | 8–12 | 6–8 | 14–18 | N/A |

Note: All values are typical and subject to batch and operational variances. HP graphite offers a robust compromise between cost and high-temperature capability, outperforming standard carbon graphite electrodes in both density and electrical/thermal properties.

3. HP Graphite Manufacturing Process Flow (with Diagram & Key Steps)

The production of hp graphite electrodes encompasses precision raw material screening, multistage forming, high-temperature graphitization, and finishing by cutting-edge CNC machining. Compliance with ISO 9001:2015 ensures high uniformity and reliability.

Process Video:

See complete hp graphite manufacturing video

- Material: 100% high-quality needle coke, premium pitch, low-sulfur (

- Machining: Multi-axis CNC lathe; socket conforms to IEC/ANSI thread standards; +/-0.5mm dimensional accuracy.

- Inspection: Each batch is tested for resistivity, mechanical strength and X-ray flaw detection. Compliance: ISO 9001:2015, ISO 14001:2015.

- End-product Testing: HP graphite is subjected to arc test, ultrasonic flaw detection, and diameter length verification.

4. Technical Advantages and Benchmarking: HP Graphite vs. Competitors

- Superior anti-oxidation longevity—by 32% over traditional carbon graphite.

- Bulk density up to 1.72 g/cm³; low porosity reduces arc burn-off rate.

- Optimized UHP socket matches increased current load, allowing safe operation up to 25 A/cm².

- Complies with ASTM C1179-18, ISO 9001 and ANSI/IEC 60672 international standards.

- Available from Ø200 mm to Ø700 mm, customizable length (1.5–2.8 m).

| Brand/Supplier | Key Advantage | Bulk Density(g/cm³) | Resistivity (μΩ·m) | Certifications | Custom Service |

|---|---|---|---|---|---|

| NL Graphite (see product) | ISO/ANSI standards, optimal pricing | 1.68–1.72 | 5.0–6.5 | ISO 9001, 14001, ANSI | Full, OEM/ODM |

| SHOWA DENKO | High-purity, long service | 1.70 | 5.7 | ISO, RoHS | Limited |

| SGL Carbon | Broad size range | 1.65–1.72 | 5.5–6.8 | ISO/IEC, EU | Available |

| HEG Ltd | Competitive pricing | 1.62–1.70 | 6.0–7.2 | ISO9000 | Limited |

5. Customization & Project Delivery: HP Graphite Tailored Solutions

- Sizes: Custom diameters (Ø200mm to Ø700mm), up to 2.8m length, UHP/HP grade, and socket threading (IEC, ANSI, pitch options).

- Grade Matching: Project-based matching for EAF power, metallurgy, silicon/ferroalloy spec.

- Surface Coating: Graphitization-enriched anti-oxidant coatings, nanolayer anti-corrosion solutions.

- OEM Branding/Packaging

- Full-Test Report Delivery: Resistivity, strength, bulk density, diametric tolerance, flaw detection with each batch.

Lead Time: Standard in-stock: 7–15 days; Bulk/MTO: 21–36 days.

Warranty: Minimum 12 months OR 100% replacement on failure due to manufacturing flaw.

Support: 24/7 tech hotline | English, Spanish, Russian, Chinese support | Installation walk-throughs included.

Certifications: All deliveries carry ISO/ANSI certificates.

Warranty: Minimum 12 months OR 100% replacement on failure due to manufacturing flaw.

Support: 24/7 tech hotline | English, Spanish, Russian, Chinese support | Installation walk-throughs included.

Certifications: All deliveries carry ISO/ANSI certificates.

6. Application Case Studies: Performance, Customer Feedback & Aftermarket

Case 1: Integrated Steel Plant (Europe, 2023)

- Application: 90-ton EAF, annual output >1.2 Mt.

- Electrode Used: 600mm, HP grade (by nlgraphite.com).

- Cycle Life Improvement: +18% vs competitor carbon graphite electrodes (measured over 600 heats).

- Power Saving: 9% lower power consumption (IEC 60672 method test report available).

- Customer Feedback: "Stable arc, less electrode consumption per ton, good adaptability for high-power operation."

Case 2: Ferroalloy Plant (Middle East, 2022)

- Electrodes: Ø400mm, UHP grade, water-cooled system.

- Results: Reduced breakage and oxidation rate; no socket failure during continuous runs (ISO 9001 audit passed).

- Feedback: "Prompt aftersale, all technical certificates provided, delivery within 18 days."

Case 3: Petrochemical Wastewater Electrolysis

- Electrodes: Custom-diameter, anti-corrosion coated, life expectancy 22 months (continuous duty).

- Feedback: "Best-in-class durability, high efficiency in alkaline/acidic condition."

Typical HP graphite Advantages in Use:

- Energy saving and arc efficiency improvement in high-load EAF.

- Corrosion resistance vital for chemical/petrochemical and environmental sector customers.

- Custom sizing and mechanical integrity support long uninterrupted production runs.

7. FAQ on HP Graphite Electrodes

-

Q1: What is the main material for hp graphite?A: 100% needle coke from oil refinery or coal tar-based sources, selected for high crystallinity and purity, fortified by premium pitch binder, enabling high conductivity and structural integrity under arc-stress.

-

Q2: What are typical sizes and length tolerances?A: Diameters usually range from 200 mm up to 700 mm; length tolerance is typically controlled to ±0.5% or ±6 mm (whichever is stricter); socket threading matches ANSI or IEC standards for fit and interchangeability.

-

Q3: How to distinguish HP and UHP graphite electrodes in performance?A: UHP electrodes offer higher flexural strength, density, and lower electrical resistivity, fit for ultra-high-power EAF states (>25 A/cm²), while HP graphite provides a balance between economy and capability in medium/high-power EAFs.

-

Q4: Which standards do qualified hp graphite products comply with?A: ISO 9001:2015, ISO 14001:2015 for quality/environment; IEC 60672 for mechanical/electrical; ASTM C1179-18 and ISO 8007 for physical testing; RoHS, EU REACH compliance available for export batches.

-

Q5: What is the delivery and installation protocol?A: Standard orders ready to ship in 7–15 days; installation guided via site diagrams and online video; technical support covers arc furnace setup, thread engagement, thermal compensation and defect avoidance measures.

-

Q6: Are OEM customization and private branding available?A: Yes, full range: branded print, custom diameter, socket, packaging, QC reports, and surface coating modifications according to customer request.

-

Q7: What after-sales services are offered for hp graphite?A: 1-year warranty; technical hotline; batch test records open for customer audit; 100% replacement for manufacturing defect; comprehensive arc performance analysis available on request.

8. Summary: Why Choose HP Graphite for Your Next Project?

- Proven in demanding EAF and chemical applications, backed by strict ISO/ANSI testing.

- Enhanced lifespan, electrical performance, and cost-efficiency vs classic carbon graphite electrode types.

- Custom engineering, third-party test certifications, and global shipment ability ensure peace of mind for high-value customers.

“According to ResearchGate 2023 report: ‘HP graphite—and especially UHP variants—are projected to become the gold standard for electric steelmaking, due to high cycle life and furnace compatibility.’”

References & Additional Reading:

- Roskill Reports: Global Trends in Graphite Electrodes

- ResearchGate: Trends in Graphite Electrode Market

- ASTM Standards: C1179-18 Test Method for Graphite Electrode

Pervious

Pervious

Next

Next