- Englist

Table of Contents: Industry Overview | Technical Specs & Process Flow | Data & Charts | Manufacturer Comparison | Applications & Case Studies | Custom Solutions | FAQ | References

1. Pyrolytic Graphite Sheet Market Insights & Emerging Trends (2024)

- Pyrolytic graphite sheet (PGS) is a high-end, man-made graphite material engineered for advanced thermal management.

- It exhibits exceptional in-plane thermal conductivity—up to 1800 W/m·K, far surpassing traditional graphite sheets and many metals.

- Applications are booming in electronics, automotive, aerospace, energy storage, and industrial sealing sectors (Market Report).

- Current industry trends:

- Miniaturization drives thinness: 0.02–1mm grades are most in demand.

- Thermal interface and EMI shielding requirements rising with 5G/EV systems.

- Emphasis on customized cutoff, lamination, and surface modification for specific applications.

- OEMs and Tier-1s requesting ISO and ANSI-compliant graphite solutions.

2. Technical Parameters & Data Sheet: Pyrolytic Graphite vs Sheet Graphite & Others

Below is a detailed technical comparison of pyrolytic graphite sheet against standard sheet graphite and premium graphite foil products. The focus is on thermal conductivity, density, flexibility, and typical application temperatures.

| Attribute | Pyrolytic Graphite Sheet | Sheet Graphite | Graphite Foil |

|---|---|---|---|

| Production Process | Chemical Vapor Deposition (CVD) | Hot Press/Calendering | Rolling/Pressing |

| Thermal Conductivity (W/m·K) | 1200~1800 (in-plane) | 350~500 | 150~300 |

| Electrical Conductivity (S/m) | ≥ 1.7×104 | ~1.1×104 | ~1×104 |

| Density (g/cm³) | 1.9~2.25 | 1.7~2.1 | 1.1~1.5 |

| Max. Working Temp (°C) | >400 (air), >3000 (inert) | ~400 | ~350 |

| Flexibility | High, ultra-thin possible | Moderate | High |

| Thickness Range | 0.02–1.0 mm | 0.1–1.5 mm | 0.05–1.5 mm |

| Certifications | ISO 9001, ANSI | ISO 9001 | ISO 9001 |

| Main Uses | Thermal management; EMI Shielding | Gasket, heat spreaders | Sealing, gaskets, flexible heaters |

3. Pyrolytic Graphite Sheet Manufacturing Process Flow

The high performance of the pyrolytic graphite sheet relies on a stringent multi-step manufacturing route, designed for optimal material purity, orientation, and structure.

Raw Material Feedstock → Purification → Chemical Vapor Deposition (CVD) → High-Temperature Annealing → CNC Cutting & Lamination → Inspection & Quality Testing (ISO 9001) → Final Packaging

Dashed arrows indicate inspection points; solid lines present the main flow.

Key Process Details

- CVD Synthesis: Ultra-pure gases (e.g., methane) decompose at 2200~3000°C, producing highly crystalline graphite layers on a substrate.

- Annealing: Orients graphite microcrystals, enhancing graphite sheet thermal conductivity and flexibility.

- Precision Cutting & Lamination: CNC machines deliver thickness control at ±0.01mm, essential for electronics and microdevices.

- Inspection & Certification: Rigorous testing under ISO 9001 and ANSI/ASTM standards ensures each batch meets global benchmarks.

- Product Longevity: Engineered for >15 years’ operational lifespan in typical electronics cooling and industrial sealing scenarios.

4. Data Visualization: Pyrolytic Graphite Sheet Technical Trends & Product Benchmarking

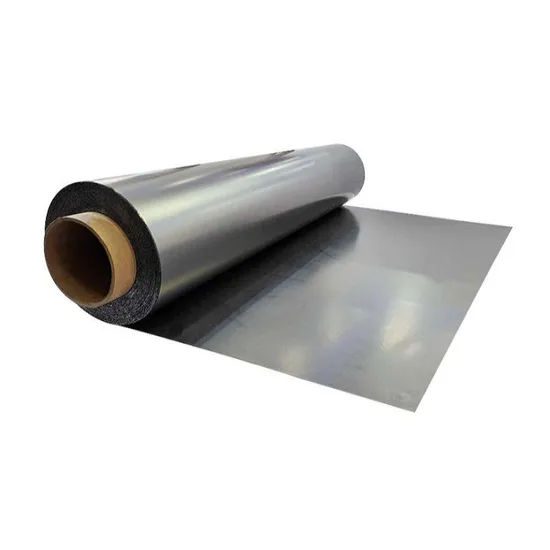

5. Product Focus: Thickness 0.2-1mm High Electric Conductivity Graphite Paper

- Nominal Thickness: 0.2, 0.3, 0.5, 0.8, 1.0mm (customizable ±0.03mm tolerance)

- In-plane Thermal Conductivity: ≥1200~1600 W/m·K (tested per ASTM E1952-17)

- Electrical Resistivity: ≤ 20 μΩ·cm

- Operating Temperature: -40°C ~ +400°C (air), up to 3000°C (inert)

- Flexural Strength: >120 MPa

- Density: 1.9–2.2 g/cm³

- Compliance: ISO 9001:2015, RoHS Compliant

- Customization: Width/length/lamination/on-site die-cutting

6. Manufacturer Comparison & Custom Solution Capabilities

| Supplier | Product Spec (thickness, size) | Thermal Conductivity (W/m·K) | Lamination Options | Certifications | Lead Time (weeks) | Customization |

|---|---|---|---|---|---|---|

| NL Graphite (NL-Advanced) | 0.2–1mm, up to 1200x500mm | 1200~1600 | Adhesive, copper, PET | ISO9001, RoHS | 2–4 | Yes (die-cut, lamination, wrap) |

| Panasonic PGS | 0.025–0.2mm, std. up to 200x400mm | 1100~1700 | PET, Al, custom | ISO9001, UL* | 6–8 | Partial |

| Graphite Central | 0.1–2mm, up to 1000x500mm | 850~1200 | PET, none | ISO9001 | 5–7 | Yes (limited) |

7. Application Scenarios: From Electronics to Chemical Industry

- Electronics: Smartphones, laptops, tablets—ultra-thin pyrolytic graphite sheet dissipates heat instantly, enabling slim form factors without performance drop.

- Automotive: Electric Vehicle (EV) battery modules use PGS for heat dissipation, protecting cells and extending battery life (Tesla, CATL supplychains).

- Industrial Sealing: Sheet graphite and graphite foil used for gaskets in oil/gas pipelines, boasting chemical inertness and long service life—even in aggressive media.

- Aerospace: EMI shielding, thin-walled heat spreaders in avionics, satellites, and UAVs.

- Petrochemical: Corrosive-resistant insulation in reactors, exchangers & process vessels.

- Water & Wastewater: Flexible graphite seals for pumps and flow meters, resisting microbial and chemical attack.

- Others: Fuel cells, flexible heaters, LED modules.

Real-World Application Case

A major EU automotive manufacturer upgraded battery cooling modules with 0.3mm NL pyrolytic graphite sheet, boosting in-plane thermal conductivity by 55% and cutting peak cell temperature by 8°C under high load—prolonging lifespan, reducing thermal runaway risk.

8. Customization Solutions & Services

- Cut-to-Size: Any width/length or die-cut complex shapes (min. dimension 1mm).

- Lamination Service: Add PET, copper, or adhesive layers for insulation, EMI, structure.

- Performance Upgrades: Hybridization for extra flexibility or higher max temperature.

- Rapid Prototyping: 3–5 days for sample delivery; batch-manufacture within 2–4 weeks typically.

- Compliance Service: Test reports supporting ISO, ASTM, RoHS, and third-party validation.

- Technical Support: 20+ years industry R&D team for integration and testing support.

- Lifetime Warranty: 2–5 years product warranty; full batch re-testing upon client request.

9. Professional FAQ: 7 Key Terms and Industry Expert Answers

Q1: What is the material structure of a pyrolytic graphite sheet?

A: It consists of ultra-fine, uniaxially oriented graphitic crystals, synthesized using Chemical Vapor Deposition (CVD) for maximum in-plane lattice alignment—resulting in world-class thermal and electrical conductivity.

Q2: What thickness tolerances can you offer for graphite sheet products?

A: Thickness control of ±0.03 mm is standard for high-end electronics-grade sheets; metrology per ISO 9506 and ANSI/ASTM D7428.

Q3: What international standards do your products comply with?

A: All NL graphite sheets comply with ISO 9001:2015, RoHS, and can be tested for ASTM, ANSI, and FDA (for sealing/food-contact) standards on request.

Q4: What is the main difference between sheet graphite, graphite foil, and pyrolytic graphite sheet in thermal management?

A: PGS exhibits 2–5x higher in-plane thermal conductivity, thinner profiles, and greater flexibility, making it the preferred solution for compact, high-performance cooling.

Q5: Which installation methods are recommended for PGS in electronics/EVs?

A: Placement between heat source and sink, direct lamination, or adhesive mounting; ensure dust-/oil-free surfaces and no creasing for maximal performance.

Q6: How is product quality and uniformity ensured in manufacturing?

A: Laser scanning, in-line thickness/impedance profiling, and final QC under ISO/ANSI standards—plus full traceability and retained samples for each batch.

Q7: What’s the typical service life under industrial or automotive conditions?

A: Tested to >15 years under cyclical thermal/chemical cycling; remains stable in structure, resistivity, and thermal conductivity. E.g., 10,000+ hour accelerated aging per ISO 11357-6.

10. Delivery, Warranty, and Customer Support

- Lead Time: Prototype samples: 3–7 days; Bulk: 2–4 weeks (custom jobs may vary).

- Warranty: 2–5 years (or per contract), covering performance and integrity under normal use.

- Customer Support: Dedicated engineer assigned; 24/7 support; remote and onsite technical consultation.

- After-sales: Batch certification, returns for defects/quality; flexible on-site revalidation for industrial customers.

- Global Logistics: Air/sea express, with export compliance for over 60 countries.

Pervious

Pervious

Next

Next