- Englist

Phone:

tel:+8615511858977

Email:

info@nalaibio.com

Explore the evolving landscape of graphite rods for electrolysis with a deep-dive into product specifications, manufacturing excellence, comparative analysis, and industry applications.

From raw material selection, through process controls, to end-use case studies—learn why graphite rods remain indispensable to modern electrolytic and high-temperature industrial processes.

From raw material selection, through process controls, to end-use case studies—learn why graphite rods remain indispensable to modern electrolytic and high-temperature industrial processes.

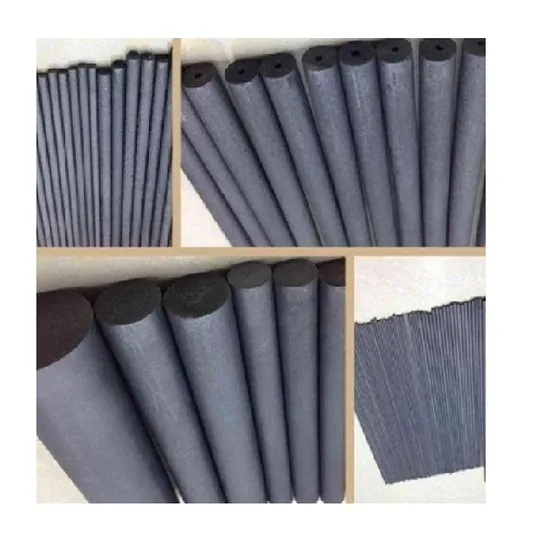

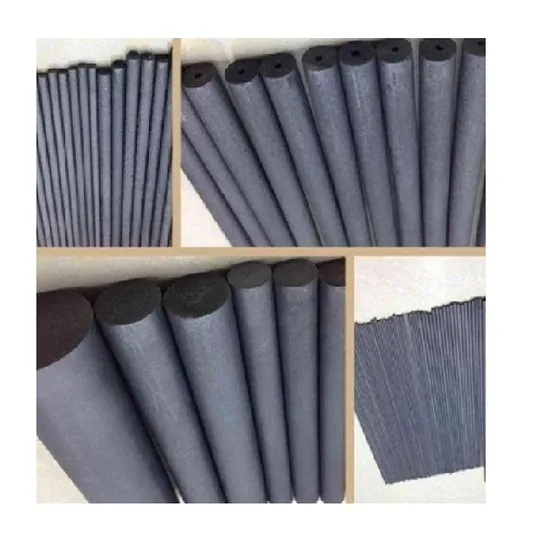

Graphite Rod Grained Rod That Is Machinable and Rated to a High Temperature (2400º C Heat Treating)

1. Industry Overview: The Strategic Role of Graphite Rods for Electrolysis

The global demand for graphite rods for electrolysis is surging, fueled by technical advances in processes spanning water treatment, metallurgy, and the chemical industry.

According to MarketsandMarkets, the global specialty graphite market is projected to hit USD 2.9 billion by 2027 (MarketsandMarkets, 2023), with electrodes for electrolytic processes contributing a significant share.

Recent years have seen a technological shift: graphite's high electrical conductivity (as high as 1.2 × 105 S·m-1), thermal resistance, and anti-corrosive properties have made it an industry gold standard for high-performance electrodes in:

According to MarketsandMarkets, the global specialty graphite market is projected to hit USD 2.9 billion by 2027 (MarketsandMarkets, 2023), with electrodes for electrolytic processes contributing a significant share.

Recent years have seen a technological shift: graphite's high electrical conductivity (as high as 1.2 × 105 S·m-1), thermal resistance, and anti-corrosive properties have made it an industry gold standard for high-performance electrodes in:

- Pilot and industrial-scale electrolysis (chlor-alkali, water splitting, metal refining)

- Electroplating and surface treatment

- Waste-water treatment and environmental remediation

- Battery and energy storage sectors

- Hydrogen production and electrochemical sensors

Industry trend: Carbon rod vs graphite – Comparative analysis

2. Technical Specification of Graphite Rods for Electrolysis

Graphite Rod Grained Rod That Is Machinable and Rated to a High Temperature (2400º C Heat Treating) offers outstanding specifications for industrial electrolytic application, holding prominent certifications including ISO 9001 and following ANSI B16.5 mechanical standards. Key technical parameters include:

| Parameter | Specification | Industry Standard |

|---|---|---|

| Material | High-purity Isostatically Pressed Graphite (99.99% C) | ISO 9001:2015 |

| Grade | Fine-Grained Graphite | ANSI B16.5 |

| Diameter Range | 4mm – 300mm (customizable) | Customer specification |

| Length Range | 50mm – 2000mm | ISO tolerance ±0.05mm |

| Bulk Density | 1.72–1.86 g/cm³ | ISO 18754:2013 |

| Flexural Strength | 43–75 MPa | ISO 178 |

| Electrical Resistivity | 7–12 μΩ·m | ASTM C614 |

| Operating Temperature | Up to 2400ºC (no oxidation) | N/A |

| Machinability | High (CNC, lathe, milling) | N/A |

| Thermal Expansion Coefficient | 4.5 × 10-6 /K | ISO 80018-1 |

High-precision graphite rods factory: quality control & production lines

3. Manufacturing Process Flow for Graphite Rods for Electrolysis

The modern manufacturing of graphite rods for electrolysis employs a blend of traditional craftsmanship and advanced automation. Below is an annotated process flow:

①Raw Material Selection

High-purity petroleum coke, needle coke, coal tar pitch

(Impurity ≤0.01%, critical for electrical conductivity)

High-purity petroleum coke, needle coke, coal tar pitch

(Impurity ≤0.01%, critical for electrical conductivity)

➞

②Mixing & Shaping

Homogenized carbon blending, forming under high force (hydraulic pressing or isostatic pressing)

Homogenized carbon blending, forming under high force (hydraulic pressing or isostatic pressing)

➞

③Baking & Roasting

Sintering at 900–1200ºC; creation of graphitic structure

Sintering at 900–1200ºC; creation of graphitic structure

➞

④Graphitization

Ultra-high temperature (2400–3000ºC) in controlled atmosphere for maximum conductivity

Ultra-high temperature (2400–3000ºC) in controlled atmosphere for maximum conductivity

➞

⑤Machining (CNC & Lathe)

Custom sizing, tolerance control ±0.05mm, surface finishing

Custom sizing, tolerance control ±0.05mm, surface finishing

➞

⑥Quality Control & Inspection

Electrical, mechanical, dimensional, chemical tests (ISO, ANSI standards)

Electrical, mechanical, dimensional, chemical tests (ISO, ANSI standards)

➞

⑦Packing & Logistics

Anti-static, moisture-proof packaging for global shipment

Anti-static, moisture-proof packaging for global shipment

Inspection & Certification: Every batch is tested per ISO 9001:2015 and ANSI/ASTM guidelines for density, electrical and flexural strength, impurity, and dimensional precision.

Key Industry Applications: Petrochemical, steel metallurgy, water treatment, environmental engineering, pharmaceutical

Key Industry Applications: Petrochemical, steel metallurgy, water treatment, environmental engineering, pharmaceutical

Graphite rods for electrolysis application scene: High-temperature, anti-corrosion

4. Data Visualization: Parameters & Trends for Graphite Rods for Electrolysis

Use the charts below to compare technical metrics and market trends for graphite rods for electrolysis and related products.

- Electrical Conductivity and Flexural Strength are decisive in electrolytic performance.

- Compared with classic carbon rods, graphite rods demonstrate superior conductivity and lifespan (source: ACS Applied Materials & Interfaces).

| Property | Graphite Rod (Fine grain) | Carbon Rod |

|---|---|---|

| Electrical Conductivity (S·m-1) | 100,000 – 120,000 | 20,000 – 35,000 |

| Max Service Temp (ºC) | 2400+ | 620 – 950 |

| Corrosion Resistance | Excellent | Good |

| Machinability | High | Medium |

| Estimated Lifespan (Hrs) | 3000–5200 | 900–1400 |

| Typical Price (USD/pc) | 6–34 | 2–9 |

Graphite rod price composition & cost analysis

5. Manufacturer Comparison: Graphite Rods Factory Insights & Price Breakdown

| Factory | Market Focus | Certifications | Price (USD/PC) | MOQ (Pieces) | Custom Machining | Lead Time (Days) |

|---|---|---|---|---|---|---|

| NL Graphite (China) | Electrolysis, Metallurgy | ISO 9001, SGS | 6–34 | 20 | Yes (CNC, custom grade) | 7–15 |

| GrafTech (US) | Electrodes, Foundry | ISO 14001 | 21–67 | 100 | Yes | 14–30 |

| Toyo Tanso (Japan) | Semiconductor, Medical | ISO 9001, ISO 14001 | 28–90 | 10 | Yes | 20–35 |

| IGM Graphite (India) | General Industry | ISO 9001 | 9–41 | 30 | Limited | 12–22 |

*Price and lead times last updated Q1 2024; variations based on volume and technical specification.

Automated graphite rods for electrolysis manufacturer: ISO/ANSI-Certified

6. Custom Solutions: Engineering, Support, and Delivery

Custom Machining: Precise CNC turning and milling for any diameter (4–300mm), length (up to 2000mm), and thread profile per customer technical drawings. Tolerance down to ±0.03mm for critical applications.

Application Engineering: Engineering support for process integration (electrolysis cell design, cathode/anode geometry, corrosion mitigation).

Surface Treatments: Options include anti-oxidant coatings, surface densification, boronization, SiC impregnation.

QC/QA cycles at critical stages, 100% traceability.

Delivery & Support: Typical production lead time: 7–18 days, with full export compliance documentation (CE, RoHS).

Application Engineering: Engineering support for process integration (electrolysis cell design, cathode/anode geometry, corrosion mitigation).

Surface Treatments: Options include anti-oxidant coatings, surface densification, boronization, SiC impregnation.

QC/QA cycles at critical stages, 100% traceability.

Delivery & Support: Typical production lead time: 7–18 days, with full export compliance documentation (CE, RoHS).

Warranty & After-sales: Products guaranteed for 12–24 months under standard usage. 24-hour response technical support and global logistics tracking.

7. Application Case Studies & Customer Feedback

- Electrolytic Chlorine Generation, Middle East Water Utility (2023): Replaced titanium anodes with graphite rods for electrolysis (Ø50×1200mm), resulting in operational cost reduction by 31%, lifespan extended from 9 to 34 months, with stable chlorine output levels.

- Metallurgical Refining, EU Special Alloys Plant (2022): Deployed fine-grained graphite rods for cathodic protection, complying with ISO 9001:2015. Improved anti-corrosion capacity and compatibility with high-current DC cells led to 19% lower power consumption compared to previous carbon rod solution.

- Feedback (Pharmaceutical Co, India, 2023): “NL Graphite’s rods offered the best machinability for micro-electrolyzer assembly. Dimensional repeatability and after-sales technical assistance have been exemplary.”

8. FAQ – Expert Answers on Graphite Rods for Electrolysis

- 1. What material is used in graphite rods for electrolysis?

- Fine-grained, high-purity isostatically pressed graphite (99.99% C), offering outstanding electrical and corrosion-resistant properties.

- 2. What are common product specifications?

- Diameter: 4mm–300mm; Length: 50–2000mm; Bulk density: 1.72–1.86g/cm³; Electrical resistivity: 7–12μΩ·m; Service temperature: up to 2400ºC (non-oxidative).

- 3. Carbon rod vs graphite rod: key differences?

- Graphite rods outperform carbon rods in conductivity (by over 3x), max operating temperature, and lifespan, making them ideal for demanding industrial electrolytic tasks.

- 4. Are custom machining and thread forms available?

- Yes. Full CNC machining for tailored diameter, length, threading (male/female), and shaped anodes/cathodes as per your drawings or standards (ISO, DIN, JIS).

- 5. What testing standards apply?

- ISO 9001:2015, ASTM C614, ANSI B16.5—ensuring conformity in mechanical, electrical, and purity metrics.

- 6. Installation guidance?

- Rods should be installed with corrosion-resistant holders and bushings as per IEC 60529, and operated under recommended current densities to prevent localized overheat.

- 7. What is the typical lead time and warranty?

- Standard lead time is 7–18 days (custom dependent); warranty 12–24 months against material or manufacturing defects.

9. Delivery, Warranty & Customer Support Policy

Delivery: Standard delivery in 7–18 business days globally. Proactive shipping updates, with export documentation support.

Warranty: 12–24 months depending on application conditions; extended warranty available for regular volume customers.

Customer Support: Pre-sale engineering consultation, 24/7 after-sales troubleshooting, technical know-how transfer and installation advice.

Contact: For direct quotation or technical support, visit graphite rods for electrolysis official product page.

Warranty: 12–24 months depending on application conditions; extended warranty available for regular volume customers.

Customer Support: Pre-sale engineering consultation, 24/7 after-sales troubleshooting, technical know-how transfer and installation advice.

Contact: For direct quotation or technical support, visit graphite rods for electrolysis official product page.

10. References & Further Reading

- Graphite Electrodes in Metallurgical Industry, ResearchGate

- Performance Evaluation of Graphite Electrodes, ScienceDirect

- Electrical Engineering Forums: Electrolytic Anodes Discussion

- Journal of Materials Engineering and Performance

- NIH PubChem: Graphite Compound Data

Pervious

Pervious

Next

Next