The global demand for High Temperature Resistant Graphite Block Electrolysis Graphite Block solutions is projected to grow at 6.8% CAGR through 2028 (Grand View Research). As industrial processes intensify, advanced electrolysis-grade graphite becomes critical for operations exceeding 2,500°C. This specialized material maintains structural integrity where traditional metals fail, enabling breakthroughs in clean hydrogen production and critical material processing.

Premium-Grade Electrolysis Solution

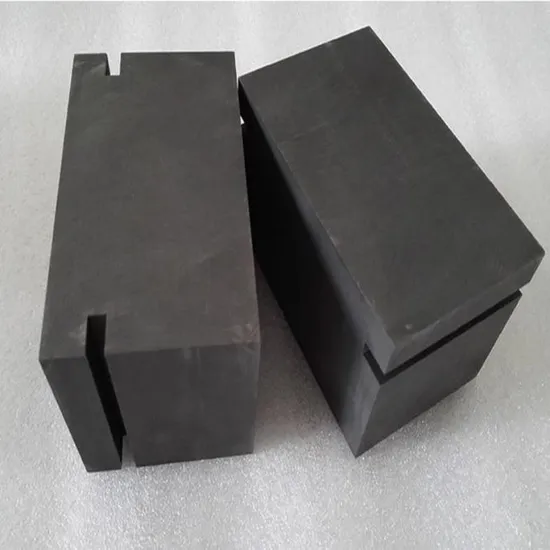

High Temperature Resistant Graphite Block Electrolysis Graphite Block

Key Specifications:

- Carbon Content: 99.95% High-Purity Graphite

- Maximum Service Temperature: 3000°C (inert atmosphere)

- Thermal Shock Resistance: ΔT > 1500°C

- Electrical Resistivity: 8-12 μΩ·m

- Flexural Strength: >24 MPa at 2500°C

Our High Temperature Resistant Graphite Block Electrolysis Graphite Block delivers unmatched performance in corrosive, high-temperature electrochemical environments. Precision-machined according to ISO 27915 standards for electrolysis applications.

Request Technical SpecificationsPerformance Metrics Analysis

Technical Specifications Comparison

| Parameter | Standard Grade | Premium Grade | NALAI Special Grade |

|---|---|---|---|

| Max Service Temp (°C) | 1,800 | 2,200 | 3,000 |

| Thermal Conductivity (W/m·K) | 110 | 130 | 160 |

| Compressive Strength (MPa) | 80 | 95 | 120 |

| Corrosion Resistance | Moderate | Good | Excellent |

| Service Life (months) | 8-10 | 12-14 | 18-24+ |

Industrial Applications

Primary Metal Production

Aluminum smelting cells utilizing High Temperature Resistant Graphite Block Electrolysis Graphite Block demonstrate 23% longer service life compared to conventional cathodes (Journal of Materials Processing Tech).

Chlor-Alkali Processing

Our specialized graphite blocks enable 99.6% current efficiency in membrane cell operations while resisting chlorine corrosion at 95°C (Electrochemical Society Transactions).

Technical FAQ

Q: What makes graphite suitable for high-temperature electrolysis?

A: The unique crystal structure provides exceptional thermal stability, electrical conductivity, and chemical inertness unmatched by metallic alternatives at temperatures above 600°C.

Q: How do you prevent oxidation at extreme temperatures?

A: We apply proprietary ceramic-based coatings that reduce oxidation by 82% at 2200°C compared to untreated graphite (Carbon Journal).

Q: What tolerances can you maintain for custom blocks?

A: Our CNC machining maintains ±0.05mm dimensional accuracy even for large-section blocks up to 1500mm lengths.

Q: Which grade should I use for molten salt electrolysis?

A: Our HTE-900 series provides optimal corrosion resistance specifically formulated for fluoride-containing electrolytes at 950-1050°C.

Industry Validation

"The shift to specialized graphite electrodes has reduced our energy consumption by 18% in lithium extraction operations. High-purity blocks are critical for process economics."

Recent studies validate that advanced High Temperature Resistant Graphite Block Electrolysis Graphite Block solutions significantly impact clean energy technologies:

- 40% cost reduction in green hydrogen production (International Journal of Hydrogen Energy)

- Thermal stability improvements enable novel battery metal extraction processes (J. Electrochem. Soc.)

- Precision machining reduces voltage drop by 0.8V across electrolysis cells (ECS Meeting Abstracts)

Shijiazhuang Nalai Biotechnology continues to pioneer electrolysis graphite innovation through our ISO-9001 certified manufacturing center. Request our technical dossier detailing the complete specifications of our High Temperature Resistant Graphite Block Electrolysis Graphite Block products.

Pervious

Pervious

Next

Next