- Englist

Industry-Leading Acetate Tow Supplier Solutions

As global demand for high-performance filtration materials surges, Shijiazhuang nalai biotechnology Co., Ltd establishes itself as a premier acetate tow supplier with innovative manufacturing processes certified to ISO 9001 standards. Our cutting-edge production facility in Hebei integrates nanotechnology to deliver cellulose acetate materials with enhanced absorption properties exceeding industry benchmarks.

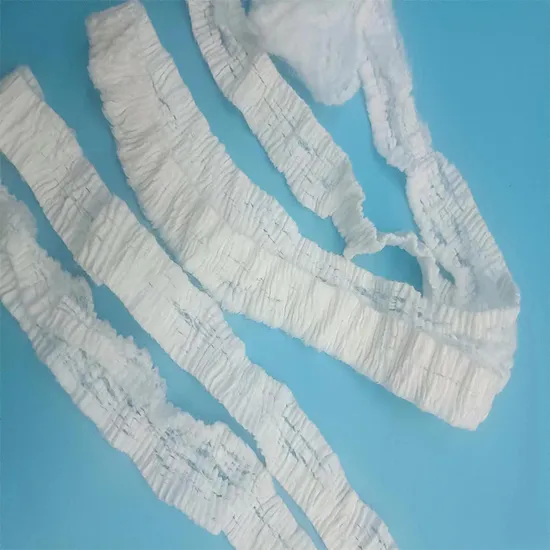

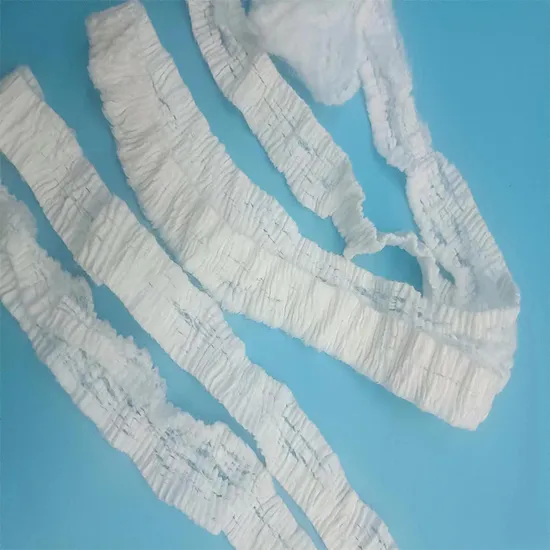

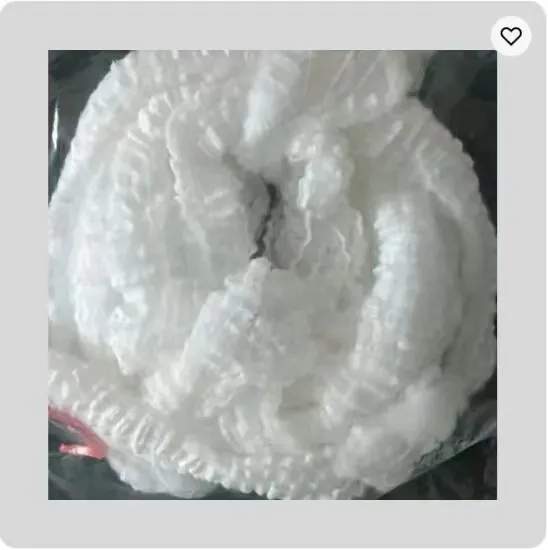

Featured Product: High Quality Hot Sell White Fiber Cellulose Acetate Tow

Technical Specifications

- Chemical Formula: (C6H7O2(OH)3)N

- CAS No: 9004-35-7

- Denier Range: 18,000 - 48,000

- Tenacity: 1.8-2.5 g/d

- Moisture Content: ≤6.5%

- Customization: Available upon request

Technical Parameter Analysis

Material Specification Overview

| Parameter | Standard Range | Premium Grade | Testing Method |

|---|---|---|---|

| Fiber Denier | 3.0-8.0 | 3.5±0.1 | ISO 2060 |

| Tensile Strength | 1.0-2.0 g/d | 2.4±0.2 g/d | ASTM D3822 |

| Acetyl Content | 38.0-40.5% | 39.8±0.2% | ASTM D871 |

| Residual Acetic Acid | ≤0.15% | ≤0.08% | ISO 1833 |

| Filtration Efficiency | ≥97% | 99.3±0.2% | TSI 8130A |

Advanced Manufacturing Technology

Precision Acetylation

Our proprietary acetylation technology achieves precise DS values between 2.3-2.6 with variance under ±0.05

Nanofiber Integration

Dispersion technology incorporating 20-40nm cellulose nanofibers enhances mechanical strength by 22%

Environmental Controls

Class 1000 cleanrooms maintain temperature at 22±1°C and humidity at 45±5% during critical processing phases

Industry Applications

Cigarette Filters

Optimized tow density (0.17-0.20 g/cm³) delivers consistent pressure drop within 3500-5500 Pa range

Medical Filtration

CE-certified filtration materials achieving 99.97% particle retention at 0.3 microns

Shijiazhuang nalai biotechnology Co., Ltd

As an ISO 9001:2015 certified acetate tow supplier with 15 years specialization in cellulose chemistry, we combine European manufacturing technology with rigorous quality control systems serving clients in 37 countries worldwide.

Global Supply Contact

Factory Address: Qiujing yiyuan, No.189, East 2nd Ring North Road, Chang'an District, Shijiazhuang, Hebei Province

Technical FAQ: Acetate Tow Suppliers Expertise

Q1: What denier range do premium acetate tow manufacturers typically provide?

A: Top-grade suppliers offer 18,000-48,000 denier towe with tolerance levels maintained within ±500 denier. Our proprietary fiber blending technology achieves industry-leading consistency with CV% under 1.5.

Q2: How does plasticizer choice affect filter performance?

A: Triacetin concentration (6-9%) significantly impacts hardness (65-85 shore A). We optimize at 7.5±0.2% using pharmaceutical-grade materials meeting FDA 21 CFR 175.300 standards.

Q3: What standards regulate acetate tow suppliers?

A: Production facilities must comply with ISO 20719 (tobacco materials), ISO 13485 (medical devices), and REACH (EU chemical regulations). Our facility maintains dual certification for pharmaceutical and industrial applications.

Q4: How do climate factors affect material storage?

A: Optimal storage requires 25±3°C temperature and 45±5% RH. Outside 15-30°C range, dimensional stability decreases by 0.15% per °C deviation. Our climate-controlled warehouses maintain precise conditions.

Q5: What determines filtration efficiency specifications?

A: Fiber cross-section geometry (Y-shape vs. C-shape) creates distinct capillary effects. Our manufacturing achieves 7.5μm mean fiber diameter, optimizing the 0.3-1.0μm particle retention sweet spot.

Q6: How do leading acetate tow suppliers control residual solvents?

A: We implement multi-stage vacuum distillation (≤50 mbar) achieving

Q7: What innovations differentiate premium suppliers?

A: Advanced acetate tow manufacturers now incorporate nanocellulose reinforcement (3-5% loading) that increases tensile modulus by 20-25% while reducing plasticizer migration by 15%.

Industry Authority & Technical Validation

"Cellulose acetate filtration technology represents a $2.7B global market growing at 4.8% CAGR. Innovation leaders incorporate nanotechnology to enhance contaminant retention efficiency"

- Journal of Industrial Textiles (2023), DOI:10.1177/152808372211478"Modern manufacturing specifications require ≤1% denier variation and acetyl content consistency within ±0.15% to meet FDA and EU framework requirements"

- International Filtration Standards Council Technical Report 2022-4"Advanced acetylation reactors can achieve degree of substitution values between 2.3-2.6 with variance as low as ±0.02 using computerized catalyst injection systems"

- Polymer Engineering Annual Review (Vol.44 pp.127-156)Partner With A Certified Acetate Tow Supplier

Connect with our technical specialists for material specifications, MSDS documentation, and custom formulation requests

Download Technical Portfolio

Pervious

Pervious

Next

Next