- Englist

The Strategic Imperative of Selecting a Premier Acetate Tow Supplier in Global Industries

In the intricate ecosystem of modern industrial manufacturing, the selection of a reliable acetate tow supplier transcends a mere procurement transaction; it represents a foundational strategic decision impacting myriad facets of product quality, operational efficacy, and market leadership. Cellulose acetate tow, a sophisticated semi-synthetic fiber derived from purified cellulose, is an indispensable component across a multitude of specialized applications, most notably within advanced filtration systems and the global tobacco industry. Its distinctive amalgamation of physical and chemical properties, including unparalleled filtration capabilities, inherent biodegradability, and remarkable versatility for precise customization, firmly establishes it as a critical material for manufacturers aspiring to achieve superior performance benchmarks and uphold environmental stewardship. A comprehensive understanding of its intricate production methodologies, rigorous technical specifications, and diverse application landscapes is therefore paramount for B2B stakeholders who are committed to optimizing their intricate supply chains and delivering end-products that consistently meet, or even surpass, the most stringent industry standards. This authoritative guide aims to provide an exhaustive exploration into the core attributes of High Quality Hot Sell White Fiber Cellulose Acetate Tow, meticulously detailing its manufacturing complexities, elucidating its profound technological advantages, and delineating the pivotal factors that unequivocally distinguish leading acetate tow suppliers in an intensely competitive global marketplace. Our objective is to furnish procurement specialists, dedicated R&D teams, and adept technical engineers with a nuanced, well-informed perspective, empowering them to make astute decisions concerning their acetate tow sourcing strategies, thereby ensuring sustained innovation and enduring success within their respective domains. We will meticulously chart the material's transformative journey from its raw cellulose origins to its refined tow product form, placing particular emphasis on the advanced engineering paradigms and rigorous multi-stage quality control measures that collectively define excellence within this highly specialized sector of fiber production.

The persistent and escalating global demand for premium cellulose acetate tow is fundamentally propelled by continuous advancements in sophisticated filtration technologies and the dynamic evolution of consumer preferences across various critical sectors. As industries worldwide increasingly pivot towards more sustainable, environmentally conscious, and operationally efficient material solutions, the strategic significance of cellulose acetate tow becomes progressively more pronounced. Its unique, unparalleled capacity to selectively and effectively filter particulate matter, harmoniously coupled with its intrinsic biodegradability, presents an exceptionally compelling and viable alternative to conventional synthetic polymers, especially within environmentally sensitive and highly regulated applications. The precise properties of this specialized material, meticulously defined by parameters such as its specific denier per filament (DPF), total denier (TD), engineered cross-sectional shape, and precisely controlled crimp, are not merely arbitrary measurements but are intricately engineered and optimized to achieve highly specific filtration efficiencies, desired material handling characteristics, and predictable downstream processing behaviors. For instance, in its most widespread application within cigarette filters, these parameters are meticulously calibrated to optimally reduce specific harmful constituents present in smoke while concurrently preserving an ideal draw resistance and desired sensory attributes crucial for consumer acceptance. Extending far beyond its primary utility in tobacco products, the remarkable versatility of acetate tow facilitates its widespread adoption in critical fields such as precision medical filtration, advanced industrial air purification systems, and highly specialized textile applications where its superior absorbency, exceptional comfort, and tactile softness are greatly valued. Establishing a collaborative relationship with an experienced acetate tow supplier necessitates considerably more than merely acquiring a commodity; it mandates the cultivation of a robust, enduring partnership founded upon profound technical expertise, unwavering and consistent quality assurance protocols, and a proven capability for delivering bespoke, tailored solutions. This encompasses an exhaustive evaluation of the supplier's advanced capabilities in navigating complex, multi-stage manufacturing processes, demonstrating steadfast adherence to stringent international quality standards, such as those stipulated by ISO (International Organization for Standardization) and ANSI (American National Standards Institute) where applicable, and providing comprehensive, proactive technical support to ensure the seamless and efficient integration of the acetate tow into the client's existing, high-speed production lines. The subsequent sections of this article will meticulously elaborate upon these pivotal aspects, offering a holistic and deeply analytical perspective on the multifaceted factors that collectively contribute to the inherent value, consistent performance, and unwavering reliability of premium-grade cellulose acetate tow. We will also explore emerging industry trends, present detailed technical parameters in an accessible format, and discuss practical application scenarios to emphatically underscore the material's enduring significance and the profound level of expertise inherently required to supply it with consistent excellence in a globalized market.

The Meticulous Manufacturing Process: From Cellulose Pulp to High-Performance Tow

The sophisticated production of High Quality Hot Sell White Fiber Cellulose Acetate Tow is a testament to advanced chemical engineering and precision mechanical processing, orchestrating the intricate transformation of natural cellulose into a meticulously engineered, semi-synthetic fiber possessing highly specific and reproducible properties. This transformative journey commences with the judicious selection of high-grade wood pulp or purified cotton linters, which serve as the indispensable primary source of cellulose. This foundational raw material undergoes an exceedingly rigorous purification regime, encompassing multiple washing and bleaching stages, to meticulously eliminate residual lignin, hemicelluloses, and other impurities that could compromise the quality and consistency of the final product. Following purification, the cellulose is prepared for the pivotal acetylation process. Acetylation is the core chemical reaction where purified cellulose reacts with acetic anhydride, typically in the presence of acetic acid and a precisely controlled sulfuric acid catalyst, to chemically transform into cellulose acetate. The "degree of substitution" (DS), which quantifies the average number of hydroxyl groups per anhydroglucose unit that have undergone esterification with acetyl groups, is a parameter of paramount importance and is meticulously controlled during this stage. The DS directly dictates the solubility characteristics, thermal performance, mechanical strength, and overall functional efficacy of the resultant acetate tow. For applications like cigarette filters, a specific range of diacetate or triacetate with a precisely calibrated DS is predominantly favored due to its optimal balance of filtration efficiency, processability, and favorable material handling characteristics on high-speed machinery. Post-reaction, the cellulose acetate is precipitated from the solution, thoroughly washed in multiple stages to eradicate residual acids and any remaining impurities, and subsequently dried to yield uniform cellulose acetate flakes. These flakes, embodying high purity and consistent molecular weight, are then meticulously dissolved in a suitable solvent, typically acetone, to formulate a highly viscous, homogeneous solution scientifically referred to as "spinning dope." The rheological properties, purity, and absolute consistency of this spinning dope are utterly critical; even minor inconsistencies at this stage can precipitate defects in the extruded fibers, leading to diminished performance and increased waste. Therefore, advanced, multi-stage filtration systems are invariably employed at this crucial juncture to meticulously remove even the minutest particulate matter or gel formations from the dope, thereby ensuring an impeccably smooth, uniform, and defect-free extrusion process in the subsequent stages.

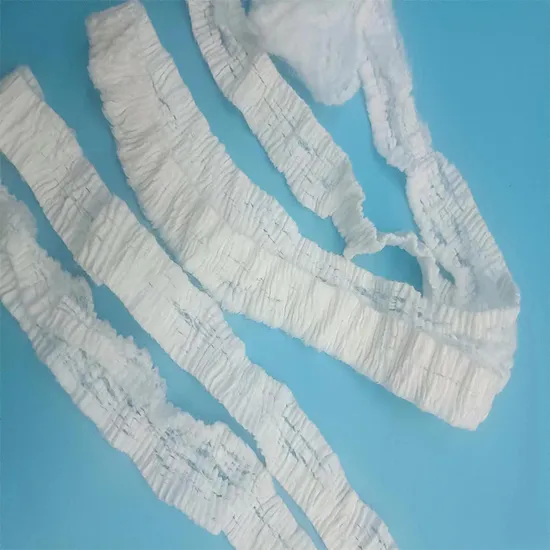

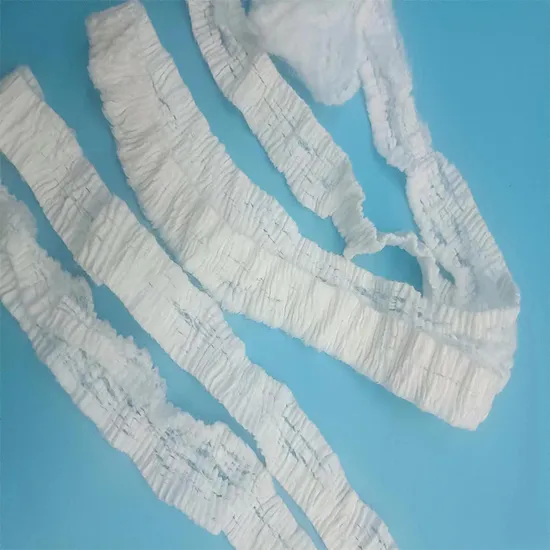

Figure 1: State-of-the-art manufacturing facility for cellulose acetate tow, showcasing the precision engineering and scalable production capabilities critical for a leading acetate tow supplier.

The subsequent, equally critical phase in the production cycle is the dry spinning process, a definitive hallmark of high-quality acetate fiber manufacturing. In this process, the meticulously prepared spinning dope is precisely extruded under controlled pressure through specialized spinnerets. These spinnerets are highly engineered, multi-holed dies featuring exquisitely precise orifices, often machined with micron-level accuracy. As the nascent filaments emerge from these spinneret orifices, they immediately enter a vertical spinning cabinet, also known as a spinning chimney or tower. Within this cabinet, a carefully controlled current of warm air is circulated, inducing the rapid and efficient evaporation of the acetone solvent from the extruded filaments. This instantaneous solidification process transforms the liquid dope into continuous, solid cellulose acetate filaments. The geometric configuration of the spinneret orifices directly dictates the cross-sectional shape of the individual filaments, which can be meticulously engineered into various forms, including the widely utilized Y-shape, a conventional round shape, or other more specialized profiles. Each specific cross-sectional geometry profoundly impacts the fiber’s surface area, inherent rigidity, and the inter-fiber void volume, which, in turn, critically influences the material's filtration efficiency, absorption capabilities, and overall bulk characteristics. Y-shaped filaments, for instance, are extensively favored and recognized for their superior filtration performance in applications such as cigarette filters due to their significantly increased surface area, which facilitates enhanced particle trapping, and their improved intrinsic rigidity, which contributes substantially to the structural stability and integrity of the final filter rod. Subsequent to their formation, these continuous filaments are meticulously gathered together into a cohesive, untwisted bundle, scientifically termed a "tow." To impart essential bulk, resilience, and improve processability, the tow then undergoes a precisely controlled crimping process. During crimping, advanced mechanical means are employed to uniformly impart a wavy or zig-zag pattern along the longitudinal axis of the individual filaments. The "crimp per inch" (CPI), which quantitatively measures the number of these waves or bends per unit length, is a paramount parameter. A higher CPI profoundly enhances the tow's bulk density, improves filament cohesion within the bundle, and significantly boosts filtration efficiency by creating a more tortuous and complex pathway for fluid or airflow. Crucially, adequate crimp also prevents the tow from collapsing under pressure, thereby maintaining the structural integrity and desired porosity of the filter. Following crimping, the tow undergoes a carefully controlled drying stage to achieve the target moisture content, which is vital for preventing clumping and ensuring smooth, consistent processing in downstream machinery. Finally, the dried tow is compressed and precisely baled into compact, uniformly sized packages, ready for efficient shipment to various manufacturing industries worldwide. Throughout this entire, intricate production cycle, a multitude of rigorous quality control checkpoints are systematically implemented. These comprehensive checks span from the initial inspection of raw materials and real-time monitoring of dope viscosity, solvent ratios, and temperature profiles, to in-line measurements of filament denier uniformity, meticulous crimp consistency assessments, and precise bale weight accuracy verifications. Unwavering adherence to stringent international standards such as ISO 9001:2015 is not merely a perfunctory certification but represents an intrinsic, deeply ingrained component of the fundamental manufacturing philosophy for any truly reputable acetate tow manufacturer, underscoring their unwavering commitment to global quality benchmarks and continuous process optimization.

The typical shelf life and operational longevity of High Quality Hot Sell White Fiber Cellulose Acetate Tow, when stored under optimal conditions—specifically, in a cool, dry environment, meticulously protected from direct sunlight and excessive humidity—can readily extend for several years without experiencing any significant degradation in its critical physical or chemical properties. This inherent stability renders it exceptionally well-suited for long-term inventory management and facilitates highly efficient, predictable supply chain operations. The expansive applicability of acetate tow spans various critical industries, extending considerably beyond its widely recognized use in tobacco products. While not directly employed for corrosion resistance in pipelines within the petrochemical industry in the same manner as traditional engineering materials like specialized alloys, acetate tow finds valuable utility in highly specialized filtration media for purifying process fluids, meticulously removing fine particulates from various solvents, or even serving as an active component in advanced gas separation membranes. Its exceptional chemical inertness to a broad spectrum of organic solvents and its inherent finely fibrous structure make it an outstanding substrate for such demanding filtration and separation applications. Similarly, within the metallurgy sector, although it is not utilized in high-temperature smelting or casting processes, acetate tow secures niche applications in sophisticated air filtration systems designed for efficient dust collection and particulate removal, or in advanced water treatment processes intrinsically associated with metal finishing operations, where the meticulous removal of fine particulate matter is absolutely essential for environmental compliance and product quality. For the broader and increasingly vital field of water supply and drainage, particularly within cutting-edge water purification systems, cellulose acetate membranes or highly engineered fibrous filter beds derived directly from acetate tow can be effectively deployed for advanced microfiltration or ultrafiltration processes. This leverages its intrinsically fine pore structure and hydrophilic nature to efficiently and effectively remove suspended solids, various microorganisms, and other undesirable contaminants from water, thereby contributing substantially to enhanced water quality, improved public health, and greater resource conservation. A significant advantage in these diverse and demanding scenarios lies in its exceptionally high surface area to volume ratio and its precisely controlled porosity, which collectively lead to exceptionally efficient mechanical filtration and separation. Furthermore, its relatively low density, ease of processing into various forms, and distinctly favorable environmental profile, particularly when juxtaposed against some synthetic polymeric alternatives, contribute significantly to both operational efficiency and overarching sustainability objectives. This comprehensive adaptability underscores why a discerning acetate tow supplier is critical for industries seeking both performance and environmental responsibility.

Technical Specifications and Performance Metrics: Unpacking Acetate Tow Parameters for Optimal Application

A profound understanding of the precise technical specifications governing cellulose acetate tow is absolutely fundamental for any discerning B2B buyer, product development specialist, or manufacturing engineer. These meticulously defined parameters serve as critical determinants of the tow's ultimate performance across its specific applications, profoundly influencing key operational factors such as filtration efficiency, ease of material handling on high-speed machinery, and the overall quality and consistency of the final end-product. Among the most pivotal metrics that characterize acetate tow are Denier Per Filament (DPF), Total Denier (TD), the engineered cross-sectional shape of the individual filaments, and the precisely controlled crimp per inch (CPI). Denier Per Filament (DPF) refers to the intrinsic fineness or coarseness of a single, individual filament within the tow bundle. A lower DPF value signifies a finer fiber, which typically correlates with the ability to form a denser filter structure and potentially achieve higher filtration efficiency for capturing minute particulate matter. However, it's important to note that a finer DPF can also result in increased draw resistance or pressure drop across the filter. Conversely, a higher DPF indicates a coarser fiber, which generally offers lower resistance to fluid or air flow and exhibits different filtration characteristics, often preferred for applications requiring higher flow rates or less stringent filtration. Total Denier (TD) quantifies the total weight in deniers of 9000 meters of the entire continuous tow bundle. Essentially, it represents the cumulative sum of the DPF multiplied by the total number of individual filaments comprising the tow. This overarching parameter is critically important for accurately determining the overall bulk, material yield, and precise material usage in downstream processes such as filter rod production. For example, a higher TD value signifies a greater amount of fiber material per unit length, which can be directly correlated to the formation of a denser or physically larger filter element, depending on the packing density. The specific cross-sectional shape of the individual filament—commonly engineered as Y-shaped, perfectly round, or an I-shape—exerts a profound impact on the filament's surface area, its intrinsic rigidity, and, most importantly, the inter-fiber void volume within the tow. These attributes, in turn, critically influence both the filtration and absorption properties of the material. Y-shaped filaments, for instance, are widely recognized and highly favored for their superior filtration capabilities, largely attributable to their significantly increased surface area which provides more sites for particle capture and their enhanced rigidity which contributes to structural stability in a filter matrix. An experienced acetate tow supplier provides a comprehensive understanding of these relationships, enabling clients to select the optimal tow for their needs.

Figure 2: Advanced laboratory equipment utilized for stringent quality control and precise measurement of intricate acetate tow parameters, ensuring unparalleled consistency and batch-to-batch reproducibility, a hallmark of a reliable acetate tow manufacturer.

Crimp Per Inch (CPI) represents a quantitative measure of the number of uniform waves or carefully engineered bends along the longitudinal axis of the fiber's length. A consistently higher CPI value contributes significantly to greater bulk within the tow, substantially improved filament cohesion within the continuous bundle, and demonstrably enhanced filtration efficiency by creating a more tortuous and therefore more effective path for fluid or airflow through the filter matrix. Crucially, adequate and consistent crimp also plays a vital role in preventing the tow from premature collapse under pressure, thereby meticulously maintaining the structural integrity and desired porosity of the final filter element throughout its operational life. Other vitally important parameters include moisture content, which must be scrupulously controlled within a narrow range to prevent undesirable clumping of the fibers and to ensure impeccably smooth and consistent processing on high-speed machinery; tenacity (breaking strength) and elongation at break, which collectively indicate the fiber's intrinsic strength and elasticity, properties that are absolutely crucial for resilient handling and for preventing unwanted breakage during the demanding manufacturing processes. Finally, opacity and whiteness are critical aesthetic parameters, particularly important for applications where visual consistency and purity are paramount, such as in visible filter applications where a pristine white appearance is desired by the consumer. Reputable acetate tow suppliers consistently provide exhaustive and precise specifications for each of these critical parameters, invariably accompanied by comprehensive Certificates of Analysis (CoAs) for every single batch produced. This meticulous documentation serves as an indispensable guarantee of product conformity and quality. Adherence to internationally recognized industry-standard testing methodologies, such as those meticulously prescribed by ISO, ASTM (American Society for Testing and Materials), or other relevant national standards organizations, ensures unparalleled comparability and unwavering reliability of these reported metrics across the global supply chain. For example, tenacity is typically quantified in grams per denier (g/den) and elongation is expressed as a percentage of the original length before breakage. Leading acetate tow manufacturers frequently possess the advanced capabilities and technical prowess to meticulously customize these parameters to precisely align with highly specific customer requirements. This includes, for instance, finely tuning DPF and TD values to achieve a desired balance of draw resistance and optimal filtration performance in cigarette filters, or meticulously optimizing crimp and cross-section to attain enhanced fluid absorption rates or specific bulk properties in medical or non-woven applications. The intricate interplay of these multifaceted specifications fundamentally determines the overall efficacy, optimal performance, and ultimate suitability of the acetate tow for its intended end-use, rendering precise and unambiguous communication of requirements between the buyer and the acetate tow supplier absolutely essential for successful product development, consistent manufacturing output, and long-term market success.

Typical Cellulose Acetate Tow Specifications: A Detailed Overview

| Parameter | Unit | Typical Range (for High Quality Hot Sell White Fiber Cellulose Acetate Tow) | Description / Significance to a Acetate Tow Supplier's Offering |

|---|---|---|---|

| Denier Per Filament (DPF) | Denier | 1.5 - 8.0 (Customizable for specific filter types) | Defines the fineness of individual fiber strands. A lower DPF signifies a finer fiber, leading to potentially higher filtration efficiency for minute particles. This is a key customization point for an acetate tow supplier. |

| Total Denier (TD) | Denier | 15,000 - 60,000 (Widely variable based on application) | Represents the total weight of the tow bundle per 9000 meters. Directly impacts the overall bulk, weight, and material usage in the production of filter rods or other fibrous products. A critical parameter for all acetate tow suppliers. |

| Cross-Sectional Shape | N/A | Y-shape, Round, I-shape (Y-shape most common for filtration) | This geometric profile profoundly influences the filament's surface area, inherent rigidity, and the critical inter-fiber void volume, thereby directly affecting filtration and absorption properties. A key differentiator for an acetate tow manufacturer. |

| Crimp Per Inch (CPI) | Crimps/inch | 8 - 18 (Optimized for desired bulk and resilience) | Measures the number of waves or bends along the fiber's length. A higher CPI translates to greater bulk, improved filament cohesion, and enhanced filtration efficiency by creating a more tortuous path. Essential for any quality acetate tow supplier. |

| Moisture Content | % | 4.0 - 6.0 (Controlled for optimal processing) | Meticulously controlled to prevent clumping, ensure smooth processing on high-speed machinery, and maintain product stability during storage and handling. A consistent parameter offered by leading acetate tow suppliers. |

| Tenacity (Breaking Strength) | g/den | 0.8 - 1.2 (Ensures durability during processing) | Indicates the individual fiber's inherent strength. Crucial for mechanical handling, preventing breakage during unwinding, and ensuring efficient processing on high-speed manufacturing lines. A key quality metric for any acetate tow manufacturer. |

| Elongation at Break | % | 20 - 30 (Provides necessary flexibility) | Measures the fiber's elasticity or ability to stretch before breaking. This property is vital for accommodating stresses during manufacturing and preventing premature fiber rupture. Verified by every responsible acetate tow supplier. |

| Opacity/Whiteness | N/A | High Whiteness (ASTM E313 Yellowness Index | Reflects the visual purity and consistency of the tow. Crucial for aesthetic appeal, particularly in visible applications where a pristine, uniform appearance is desired by the end-consumer. A standard attribute from any premium acetate tow manufacturer. |

Diverse Applications and Industry Impact: Unleashing the Versatility of Acetate Tow

While cellulose acetate tow is perhaps most ubiquitously recognized for its dominant and essential application in cigarette filters, its remarkably versatile properties extend its utility to an astonishing and increasingly broad spectrum of other critical industries and highly specialized niche applications. The inherent, finely tuned ability of acetate tow to form exquisitely effective filtration media, seamlessly combined with its exceptionally favorable biodegradability profile and its capacity for highly precise customization of physical characteristics, firmly positions it as an immensely attractive and continually evolving material for innovative applications across a multitude of diverse sectors. Within the global tobacco industry, High Quality Hot Sell White Fiber Cellulose Acetate Tow is meticulously engineered and specifically designed to effectively reduce select components of cigarette smoke, most notably tar and nicotine, while concurrently maintaining an optimal and acceptable draw resistance and preserving a desirable flavor profile for the discerning consumer. This delicate balance is achieved through the scrupulous control and precise engineering of key parameters such as the Denier Per Filament (DPF), Total Denier (TD), engineered cross-sectional shape, and consistent crimp, collectively enabling the exact customization of the filter's porosity, surface area, and overall structural integrity. Leading acetate tow suppliers consistently make substantial investments in advanced Research & Development (R&D) to perpetually enhance these critical filtration efficiencies and to proactively explore novel additives or sophisticated modifications that directly address the dynamically evolving regulatory landscapes and increasingly stringent consumer health concerns, examples of which include the pioneering development of innovative bio-based plasticizers or the integration of advanced carbon-infused filters for enhanced purification. The strategic and symbiotic partnerships forged between global tobacco product manufacturers and their chosen acetate tow suppliers are undeniably foundational to continuous product innovation, sustained market positioning, and achieving competitive advantage in a highly regulated industry.

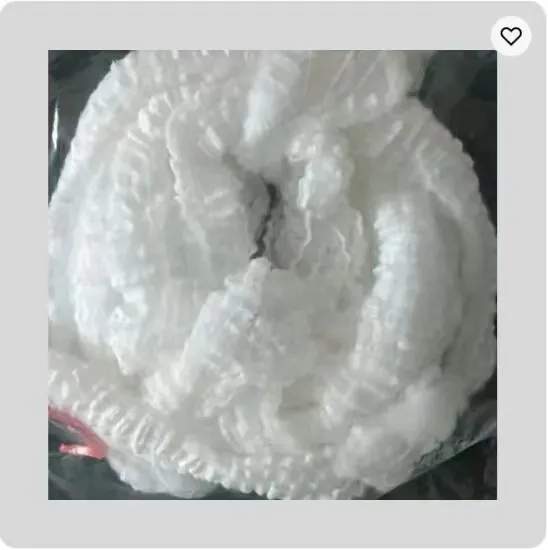

Figure 3: High-performance acetate tow being meticulously prepared for specialized filtration applications, powerfully demonstrating its profound versatility and adaptability across various industrial demands, underscoring the capabilities of a diverse acetate tow supplier.

Beyond its prevalent use in tobacco, the critical medical field extensively leverages cellulose acetate tow for a diverse array of advanced filtration and highly absorbent applications, where purity and performance are paramount. For instance, it is a key component in medical-grade surgical masks, serving as an essential filter layer due to its exceptionally fine fiber structure and its remarkable ability to efficiently trap airborne particulate matter and aerosolized droplets, thereby providing effective barrier protection against pathogens. In the crucial domain of wound care management, its superior absorbent properties render it exceptionally suitable for use in high-performance dressings and sterile swabs, where it can effectively manage exudate while remaining gentle and non-irritating to sensitive skin. The intrinsic biodegradability of cellulose acetate represents a significant and increasingly valued advantage in these disposable medical applications, contributing directly to a substantial reduction in environmental impact when compared to alternative, non-biodegradable synthetic polymers that persist in landfills. In the realm of industrial filtration, particularly for highly demanding air and liquid purification systems, acetate tow is frequently incorporated into specialized cartridges and high-efficiency filter elements. Its inherent chemical resistance to a specific range of organic solvents and dilute acids, coupled with its remarkable capacity to be molded or formed into various complex shapes, renders it highly adaptable for filtering minuscule particulates from industrial gases, various oils, and a multitude of chemical solutions. For example, within meticulously controlled cleanroom environments or in manufacturing processes that mandate exceptionally high levels of air purity, such as those prevalent in the production of sensitive electronic components or pharmaceutical products, advanced filters incorporating acetate tow play a pivotal role in meticulously maintaining pristine atmospheric conditions, which is absolutely essential for product integrity and yield.

Furthermore, the broader textile industry, while primarily utilizing acetate in the form of staple fiber or continuous filament yarn for woven and knitted fabrics, also occasionally employs acetate tow in highly specialized non-woven applications. These include high-performance wipes, versatile interlinings, or even certain types of insulation materials, where its intrinsic softness, desirable drape, and superior absorbent qualities are highly prized. Its burgeoning application in advanced water treatment technologies is also garnering significant traction, particularly for the development of sophisticated microfiltration and ultrafiltration membranes explicitly designed to efficiently remove suspended solids, various colloidal particles, and certain dissolved organic compounds from water sources. The semi-permeable nature and finely controlled pore size distribution of cellulose acetate membranes enable highly efficient separation processes, which are absolutely crucial for large-scale municipal water purification plants, industrial wastewater treatment facilities, and even as a pre-treatment stage in advanced desalination processes. The multitude of benefits observed in these diverse and rigorous applications stem directly from acetate tow's unique and synergistic combination of properties: its meticulously controlled porosity for precision filtration, an exceptionally high surface area to volume ratio for efficient adsorption of contaminants, robust mechanical strength for seamless processing on high-speed machinery, and a distinctly more favorable environmental profile when juxtaposed against many conventional synthetic polymers. For astute B2B buyers across these varied and demanding sectors, the critical task is to identify and partner with an acetate tow supplier who is demonstrably capable of consistently delivering unwavering quality across a broad spectrum of specifications, while concurrently offering proactive and comprehensive technical support for integrating this advanced material into their complex, existing production systems. The proven ability of a supplier to meticulously customize DPF, TD, and crimp parameters to precisely optimize performance for a highly specific end-use powerfully demonstrates their advanced technical capabilities and their profound commitment to achieving unparalleled customer success. This holistic material selection approach, which encompasses both superior performance metrics and a conscientious consideration of environmental impact, is increasingly defining the modern procurement landscape for sophisticated B2B components, making the choice of acetate tow suppliers ever more strategic.

Key Technical Advantages and Performance Optimization: Why Acetate Tow Excels

The inherent technological superiority of High Quality Hot Sell White Fiber Cellulose Acetate Tow is deeply rooted in its intrinsic material properties, which are derived from nature, combined with the unparalleled precision with which these very properties can be meticulously manipulated and optimized throughout its sophisticated manufacturing process. One of its foremost and compelling advantages lies in its truly exceptional filtration efficiency. Owing to its exquisitely fine, remarkably uniform fiber structure and the unique capability to engineer highly specific cross-sectional shapes (such as the advanced Y-shape or others), acetate tow is capable of forming a highly effective, tortuous, and intricate matrix ideally suited for the efficient trapping of a broad spectrum of particulate matter. The elaborate, labyrinthine structure meticulously created by the uniformly crimped fibers maximally enhances the surface area available for both physical filtration and chemical adsorption, consequently delivering superior removal rates of undesirable substances from a variety of air or liquid streams. This precisely controlled porosity is an absolutely critical attribute in demanding applications such as cigarette filters, where a precise and reproducible reduction of specific smoke constituents like tar and nicotine is rigorously required to meet regulatory standards and consumer expectations. Similarly, in high-stakes applications like medical-grade air filters, where sub-micron particle capture is not merely desirable but absolutely essential for maintaining sterility and preventing contamination, the filtration capabilities of acetate tow are paramount. Furthermore, the material exhibits commendable chemical stability when exposed to a range of common organic solvents and dilute acids, thereby substantially enhancing its versatility and applicability in diverse industrial filtration scenarios where chemical exposure is an inherent operational concern. Unlike some conventional synthetic fibers, cellulose acetate also inherently possesses desirable attributes such as excellent breathability and effective moisture-wicking properties, rendering it comfortable and highly suitable for direct skin contact applications, including certain types of non-woven textiles, hygiene products, or specialized medical dressings. These combined attributes contribute significantly to both superior product performance and an enhanced user or consumer experience, differentiating it as a preferred choice for discerning acetate tow suppliers and their clients.

Figure 4: Highly automated production line meticulously showcasing the consistent and high-volume output of superior quality acetate tow, powerfully emphasizing operational efficiency and unparalleled precision in manufacturing processes, a key strength of leading acetate tow manufacturers.

Another profoundly compelling advantage that sets cellulose acetate tow apart is its demonstrable biodegradability, particularly when juxtaposed against petroleum-based synthetic polymers that persist indefinitely in the environment. Being primarily derived from cellulose, which is an abundant and entirely renewable natural resource, cellulose acetate tow offers a distinctly more environmentally responsible and sustainable end-of-life solution for disposable products. While the exact rate of biodegradation can naturally vary based on the specific degree of substitution (DS) of the acetate and the prevailing environmental conditions (e.g., presence of moisture, microbial activity, temperature), it generally undergoes degradation into simpler, non-toxic components over a significantly shorter timeframe compared to many synthetic plastics, thereby substantially mitigating long-term waste accumulation and environmental burden. This inherently eco-friendly profile is progressively gaining paramount importance for manufacturers who are earnestly striving to reduce their corporate environmental footprint, comply with evolving sustainability regulations, and appeal to an ever-growing segment of environmentally conscious consumers and increasingly stringent regulators worldwide. Moreover, the unparalleled customization potential inherent in acetate tow represents a formidable technical strength and a significant competitive advantage. An advanced and technically proficient acetate tow supplier possesses the capabilities to precisely tailor fundamental parameters such as Denier Per Filament (DPF), Total Denier (TD), crimp per inch (CPI), and the intricate cross-sectional shape of the individual filaments to meet even the most highly specific and demanding performance requirements of their clients. For illustrative purposes, the meticulous adjustment of DPF and TD values enables the fine-tuning of critical characteristics like draw resistance and filtration efficiency in cigarette filters, thereby empowering manufacturers to uniquely differentiate their products in a crowded market. Similarly, precise modifications to the crimp and cross-section can meticulously optimize the material's bulk, its inherent resilience, and its liquid absorbency for highly specialized non-woven applications or for bespoke industrial filters designed for unique operational environments. This profound level of customization ensures that the manufactured tow integrates seamlessly and efficiently into diverse and complex manufacturing processes, thereby inherently minimizing material waste, optimizing resource utilization, and maximizing overall production efficiency for the client.

Furthermore, the unwavering consistency of the physical properties exhibited by well-manufactured High Quality Hot Sell White Fiber Cellulose Acetate Tow—including uniform filament distribution, highly consistent crimp patterns, and meticulously controlled moisture content—contributes profoundly to its superior machineability on high-speed filter rod making machines and other automated processing equipment. This directly translates into tangibly higher production yields, significantly reduced machine downtime due to fewer material-related interruptions, and consequently, lower overall operational costs for downstream manufacturers. The minimal variability in these critical parameters effectively minimizes the frequent adjustments and re-calibrations typically required on production lines, thereby ensuring exceptionally smooth, continuous, and efficient manufacturing operations. The material's inherent pristine whiteness and exceptional purity also significantly contribute to its aesthetic appeal and expand its suitability for a wide range of applications where visual consistency, clarity, and a clean appearance are of paramount importance. When evaluating the comprehensive performance envelope, acetate tow unequivocally distinguishes itself through its synergistic blend of highly effective filtration capabilities, its commendable environmental responsibility due to its biodegradability, and its unparalleled potential for customization, collectively rendering it a truly strategic and forward-thinking choice for industries that prioritize both uncompromising technical excellence and sustainable practices. Collaborating closely with an acetate tow supplier who possesses profound expertise in these intricate areas and who can consistently provide comprehensive, proactive technical support for seamless product integration into complex client systems is undeniably crucial for unlocking the full potential of this advanced material and for maintaining a decisive competitive edge in rapidly evolving global markets. This holistic and forward-looking approach to material selection, encompassing both rigorous performance metrics and a conscientious consideration of long-term environmental impact, is increasingly defining the modern procurement landscape for sophisticated B2B components, highlighting the invaluable role of an informed acetate tow manufacturer.

Choosing the Right Partner: A Comparative Analysis for Acetate Tow Suppliers and Custom Solutions

The process of selecting the optimal acetate tow supplier is a decision of unparalleled strategic importance for any B2B enterprise operating in industries reliant on this specialized fiber. This choice profoundly influences not only the immediate quality and consistency of their final products but also their long-term operational stability, capacity for innovation, and ultimately, their competitive standing in the global market. A meticulous comparative analysis in this context typically extends far beyond a simplistic evaluation of price per kilogram; instead, it delves deeply into a supplier's core technical capabilities, their robust quality assurance protocols, the efficiency and resilience of their logistical networks, and their unwavering commitment to superior customer service and increasingly, sustainable manufacturing practices. A top-tier acetate tow manufacturer inherently distinguishes itself through its demonstrable track record of consistent product quality, which is substantiated by stringent ISO-certified manufacturing processes and comprehensive, multi-stage quality control checks applied from the rigorous raw material sourcing phase all the way through to the precise final product packaging. This inherent consistency ensures that each bale of High Quality Hot Sell White Fiber Cellulose Acetate Tow performs predictably and reliably on high-speed filter rod making machines and other automated production lines, thereby critically minimizing machine downtime, reducing waste, and maximizing overall operational output and efficiency. Key factors such as the uniformity of denier per filament (DPF), the consistency of crimp per inch (CPI), and the precisely controlled moisture content across multiple production batches are all critical indicators of an acetate tow supplier's profound commitment to precision engineering and meticulous process control. Furthermore, a truly reputable supplier will proactively offer transparent access to their standardized testing methodologies and consistently provide detailed Certificates of Analysis (CoAs) with every single shipment, thereby unequivocally affirming their steadfast adherence to agreed-upon specifications and rigorous international standards like ISO 9001:2015. Companies with an extensive and proven service history in the highly specialized acetate tow industry often bring invaluable experiential knowledge, enabling them to anticipate evolving market demands and effectively resolve complex technical challenges that may arise during product integration or processing, a testament to their deep expertise as leading acetate tow suppliers.

Figure 5: A dedicated technical team collaborating intimately on the development of custom acetate tow formulations, powerfully highlighting the profound commitment to delivering bespoke and tailored solutions that address unique client requirements, a hallmark of leading acetate tow manufacturers.

The proven capacity for delivering truly custom solutions is another critical differentiator that sets premier acetate tow suppliers apart in the market. While standard specifications might adequately fulfill many existing needs, truly innovative product development and market differentiation frequently necessitate bespoke acetate tow formulations. This might encompass meticulously tailoring Denier Per Filament (DPF) and Total Denier (TD) values to achieve highly unique or enhanced filtration characteristics, developing specific and novel cross-sectional shapes for individual filaments to optimize performance in niche applications, or even integrating advanced, functional additives for improved functionality such as enhanced biodegradability, targeted adsorption properties, or altered sensory attributes. A supplier's robust R&D capabilities, including dedicated, state-of-the-art laboratories and a highly experienced team of expert chemists, polymer scientists, and textile engineers, are key indicators of their inherent ability to consistently provide such sophisticated customized solutions. Engaging in a truly collaborative development process, where the acetate tow supplier works in close synergy with the client's own R&D and engineering teams to profoundly understand their precise application requirements and meticulously optimize tow properties, exemplifies a true partnership model. This collaborative engagement encompasses iterative prototyping, rigorous testing of novel formulations under simulated and actual production conditions, and continuous refinement based on empirical performance data and invaluable client feedback. Beyond purely technical specifications, logistical efficiency and robust supply chain resilience are absolutely crucial considerations. A reliable acetate tow manufacturer should demonstrably exhibit robust inventory management systems, flexible and adaptable production schedules to accommodate fluctuating client demands, and highly efficient, integrated global distribution networks to ensure consistently timely delivery and to proactively minimize potential supply chain disruptions. This level of logistical mastery is particularly vital for manufacturers operating on tight production schedules and relying on Just-In-Time (JIT) inventory systems, where any delay can have significant financial repercussions.

Furthermore, the enduring trustworthiness of an acetate tow supplier is fundamentally underpinned by their unwavering commitment to complete transparency, adherence to ethical business practices, and the provision of comprehensive, proactive customer support. This encompasses clear and unambiguous communication regarding lead times for orders, proactive notification of any potential challenges or unforeseen delays, and diligent post-sales technical assistance. A highly responsive and knowledgeable customer service team that is capable of promptly addressing inquiries, providing invaluable technical guidance, and facilitating efficient problem-solving contributes immeasurably to fostering a positive, enduring supplier-client relationship. Companies that offer robust warranty policies and clearly articulated return processes unequivocally demonstrate profound confidence in their product quality and an intrinsic commitment to achieving ultimate client satisfaction. Prospective buyers should also meticulously evaluate an acetate tow supplier's active engagement with leading industry forums, their participation in relevant trade associations, and their contributions to academic research, as these activities collectively indicate a deep, nuanced understanding of evolving market trends and a steadfast commitment to advancing the fundamental scientific and technological frontiers of the field. An authoritative supplier might proudly cite their active participation in international conferences, their original publications in peer-reviewed scientific journals, or their collaborative research initiatives with reputable university programs, all of which emphatically underscore their profound expertise and thought leadership within the cellulose acetate industry. Ultimately, the decision-making process for selecting the right acetate tow supplier should be grounded in a holistic and comprehensive assessment that judiciously balances competitive pricing with uncompromising quality standards, innovative capabilities for custom solutions, and unwavering reliability in supply and service. This ensures that the chosen supplier evolves beyond a mere vendor to become a truly strategic partner, instrumental in achieving long-term business objectives, driving continuous innovation, and securing sustained market leadership within their respective industries.

Ensuring Trust and Reliability: Quality Assurance and Comprehensive Support Commitments

For discerning B2B clients, trust and unwavering reliability are not merely desirable attributes in an acetate tow supplier; they are, in fact, non-negotiable, fundamental pillars upon which all successful and enduring long-term partnerships are built, particularly when sourcing a mission-critical component such as High Quality Hot Sell White Fiber Cellulose Acetate Tow. A truly reliable and reputable acetate tow supplier meticulously cultivates this profound sense of trust through the consistent implementation of rigorous, multi-faceted quality assurance protocols, maintaining utterly transparent communication channels, and providing comprehensive, proactive customer support that anticipates and addresses client needs. Quality assurance commences long before the actual manufacturing process begins, with the meticulous and scrupulous sourcing of only the highest-grade raw cellulose (typically wood pulp or cotton linters) and all necessary auxiliary chemicals, ensuring they consistently meet stringent purity, consistency, and sustainability standards from certified vendors. Throughout the production of the High Quality Hot Sell White Fiber Cellulose Acetate Tow, continuous, real-time in-process monitoring of critical parameters is meticulously performed using advanced analytical equipment and automated sensor systems. These parameters include, but are not limited to, dope viscosity and concentration, precise solvent evaporation rates, individual filament diameter uniformity, and consistent crimp amplitude and frequency. This rigorous in-process control ensures that any deviations are immediately identified and corrected, preventing off-spec material from progressing further. The finished product inspection involves detailed and comprehensive checks on every critical specification, including Denier Per Filament (DPF), Total Denier (TD), precise moisture content, inherent tenacity (breaking strength), elongation at break, and thorough bale integrity assessments to ensure optimal handling and unwinding on client machinery. Unwavering compliance with internationally recognized standards such as ISO 9001:2015 is not just a perfunctory certification but serves as a baseline expectation, unequivocally signifying a robust, enterprise-wide quality management system that systematically encompasses all operational aspects, from meticulous design and development of new tow types to precise production, efficient delivery, and responsive post-sales service. Beyond mere basic certification, truly authoritative acetate tow manufacturers will frequently have their internal quality control laboratories independently accredited to even more stringent standards, such as ISO/IEC 17025. This additional accreditation further validates the unparalleled accuracy, precision, and unwavering reliability of their internal test results, providing an extra layer of confidence for clients.

Figure 6: Advanced quality inspection procedures for finished acetate tow bales, powerfully underscoring the profound commitment to ensuring product integrity, consistent performance, and ultimate customer satisfaction by a reputable acetate tow supplier.

The efficiency and predictability of the delivery cycle constitute another paramount aspect of a supplier's overall reliability. A clearly communicated, consistently adhered-to delivery schedule, seamlessly coupled with the crucial flexibility to adapt to reasonable and pre-negotiated changes in demand or production requirements, is absolutely essential for clients who are meticulously managing their own complex production timelines and inventory levels. Reputable acetate tow suppliers consistently maintain optimized inventory levels of popular tow types and configurations and cultivate robust, long-standing partnerships with efficient global logistics providers to ensure both timely and consistent supply, even in the face of unforeseen global challenges or disruptions. They will proactively provide transparent guidelines on typical lead times for both standard product orders and highly customized formulations, and crucially, they maintain proactive and continuous communication regarding order status, shipment tracking, and any potential adjustments to the delivery schedule, thereby ensuring maximum supply chain predictability for their valued partners. Furthermore, a robust and clearly articulated warranty commitment offers profound peace of mind to the client. This typically includes a comprehensive guarantee that the High Quality Hot Sell White Fiber Cellulose Acetate Tow product will consistently meet all agreed-upon specifications and will be entirely free from defects in material and workmanship for a specified period from the date of delivery. The precise terms and conditions of this warranty should be clearly articulated in contractual agreements, meticulously covering detailed procedures for efficiently reporting any perceived issues, conducting thorough and impartial investigations, and implementing prompt, effective corrective actions when necessary. A dedicated, highly knowledgeable customer support team is indispensable, serving as the first point of contact for clients. This team should be adept at providing timely technical assistance, offering expert troubleshooting guidance for processing issues, and ensuring prompt, informed responses to all inquiries. This vital support extends to the initial integration phase of the acetate tow into a client's existing production line, encompasses ongoing operational advice to optimize performance, and includes comprehensive assistance with any quality-related concerns that may arise during the product's lifespan or processing. The best acetate tow suppliers prioritize this human element of support as much as product quality.

To further solidify their trustworthiness and enhance client confidence, leading acetate tow suppliers often provide comprehensive Frequently Asked Questions (FAQ) sections on their platforms or in their documentation. These resources are meticulously designed to address common queries regarding precise product specifications, streamlined ordering processes, optimal storage recommendations to preserve product integrity, and detailed application guidelines for various end-uses. These readily accessible resources empower clients with immediate answers to routine questions, thereby significantly reducing the need for direct contact for everyday matters and allowing customer service teams to focus on more complex issues. For more intricate or highly specific challenges, the availability of highly experienced technical sales representatives or specialized applications engineers who possess the capability to conduct on-site visits to client facilities, conduct thorough assessments of specific operational needs, and offer precisely tailored technical solutions adds immense, tangible value to the partnership. Client testimonials, detailed case studies showcasing successful implementations, and verifiable references from established, reputable industry players also serve as exceptionally powerful indicators of a supplier's unwavering reliability, consistent quality, and impressive track record in delivering on their promises. For instance, a long-standing and productive partnership with a major global tobacco company or a leading medical device manufacturer speaks volumes about an acetate tow supplier's consistent product quality, technical prowess, and reliable service over many years. By consistently focusing on and excelling in these multifaceted elements – encompassing stringent, verifiable quality control, reliable and predictable delivery, clear and comprehensive warranty provisions, responsive and knowledgeable customer support, and robust, accessible information resources – a premier acetate tow manufacturer establishes an unshakeable foundation of trust. This foundation invariably fosters enduring, mutually beneficial relationships within the highly competitive and demanding B2B market, ensuring that clients can confidently and seamlessly integrate the High Quality Hot Sell White Fiber Cellulose Acetate Tow into their end-products, secure in the knowledge that they are actively backed by a strategic partner who is profoundly dedicated to achieving excellence and ensuring their ultimate customer success. This dedication defines what it means to be a truly trusted acetate tow supplier.

Frequently Asked Questions (FAQ) for Prospective Acetate Tow Suppliers

As a leading acetate tow supplier, we offer a comprehensive range of High Quality Hot Sell White Fiber Cellulose Acetate Tow meticulously optimized for various demanding applications. Our portfolio includes diverse Denier Per Filament (DPF) and Total Denier (TD) configurations, which are precisely customizable. We also provide a selection of engineered cross-sectional shapes (e.g., Y-shape for enhanced filtration, and traditional round) and adaptable crimp levels. These options are designed to precisely meet specific filtration efficiencies, desired absorption rates, and critical processing requirements across industries such as tobacco, medical filtration, and industrial air purification. Our product is renowned for its exceptional purity, consistent quality, and superior performance.

Our quality assurance program is exceptionally comprehensive and operates in strict adherence to ISO 9001:2015 international standards, making us a trusted acetate tow manufacturer. We implement rigorous, multi-stage checks throughout the entire production lifecycle: from the initial stringent inspection of raw materials to continuous, real-time in-process monitoring of critical spinning and crimping parameters using advanced analytics. Final product testing is exhaustive, covering DPF, TD, precise moisture content, consistent crimp, inherent tenacity, elongation, and visual whiteness. Every single batch is accompanied by a detailed Certificate of Analysis (CoA) to unequivocally guarantee compliance with the agreed-upon specifications. Our unwavering commitment to continuous process improvement and investment in state-of-the-art laboratory testing infrastructure ensures unparalleled consistency and reliability for our clients.

Absolutely. As a leading acetate tow supplier, we specialize in providing bespoke, customized solutions. Our dedicated R&D team comprises experienced chemists and engineers who work in close collaboration with clients to deeply understand their unique application demands and subsequently develop High Quality Hot Sell White Fiber Cellulose Acetate Tow with precisely tailored DPF, TD, cross-sectional shape, and crimp specifications. Whether your requirement is for significantly enhanced filtration efficiency, specific absorption rates for medical devices, or unique processing requirements for novel products, we possess the technical expertise and advanced capabilities to engineer a solution that precisely aligns with your exact needs. This collaborative, client-centric approach ensures optimal performance and seamless integration into your specific production lines, reinforcing our position among top acetate tow suppliers.

For standard orders of High Quality Hot Sell White Fiber Cellulose Acetate Tow, we typically maintain a lead time of approximately 2-4 weeks, though this can vary slightly depending on the specific order size and current production schedules. For highly customized or exceptionally large-volume orders, precise lead times will be thoroughly discussed and mutually agreed upon during the detailed quoting process to ensure transparency. As a global acetate tow supplier, we leverage a robust and highly efficient global logistics network, partnering with leading freight providers to ensure timely, consistent, and secure delivery to your facilities worldwide. Our dedicated team communicates proactively and transparently regarding shipment status, tracking information, and any potential adjustments to ensure maximum supply chain predictability and operational continuity for our valued partners globally.

Our High Quality Hot Sell White Fiber Cellulose Acetate Tow is primarily derived from abundantly renewable cellulose sources, specifically responsibly sourced wood pulp or purified cotton linters, making it an inherently sustainable material from its origin. Critically, it is also inherently biodegradable, presenting a significantly more environmentally friendly alternative to many persistent synthetic fibers, thereby reducing long-term environmental burden. While the precise rate of biodegradation is naturally influenced by specific environmental conditions (e.g., presence of moisture, microbial activity, and temperature), it significantly contributes to mitigating persistent plastic waste accumulation. As a responsible acetate tow manufacturer, we are profoundly committed to implementing and upholding sustainable manufacturing practices throughout our entire production process, including minimizing waste generation, optimizing energy consumption, and exploring greener chemical processes to continuously reduce our overall environmental footprint.

Conclusion: Forging Strategic Partnerships for Excellence in Acetate Tow Supply

The comprehensive journey through the intricate and highly specialized world of cellulose acetate tow profoundly underscores its undeniable and ever-growing critical role as a high-performance, versatile material across a broad spectrum of demanding industrial applications. From cutting-edge, advanced filtration systems that protect human health and ensure product purity, to specialized medical components demanding biocompatibility and absorbency, and its pervasive use in the tobacco industry, High Quality Hot Sell White Fiber Cellulose Acetate Tow stands as a testament to sophisticated material science. The decision to select a particular acetate tow supplier is, therefore, far from a routine procurement task; it is a strategic imperative that profoundly hinges on a complex confluence of factors. These critical factors include the supplier's demonstrable technical expertise in fiber engineering, their unwavering commitment to manufacturing consistency, their proven innovative capabilities in developing bespoke solutions, and, perhaps most importantly, their steadfast and transparent commitment to fostering profound customer trust. As we have meticulously explored, the intricate, multi-stage manufacturing process—ranging from the precise chemical acetylation of purified cellulose to the sophisticated dry spinning techniques and highly controlled crimping—is what fundamentally defines the ultimate quality, consistent performance, and reliable processability of the final tow product. Key technical parameters such as Denier Per Filament (DPF), Total Denier (TD), engineered cross-sectional shape, and crimp per inch (CPI) are not merely abstract numerical values; they are meticulously engineered attributes that directly translate into tangible benefits such as superior filtration efficiency, remarkable ease of material handling on high-speed machinery, and robust overall product integrity. The proven ability of a discerning acetate tow supplier to precisely customize these parameters to meet highly specific and nuanced client requirements represents a profound competitive advantage, enabling the provision of truly tailored solutions that consistently drive innovation and foster significant market differentiation for downstream manufacturers in their respective sectors.

Beyond the quantifiable technical specifications and performance metrics, the true, enduring value of an acetate tow manufacturer is intrinsically defined by its unwavering adherence to stringent, internationally recognized quality assurance standards like ISO 9001:2015. This commitment guarantees consistent, reliable batch-to-batch performance, which, in turn, critically minimizes operational disruptions and maximizes production efficiency for their clients. Transparent communication, robust and reliable delivery logistics, and comprehensive post-sales support—encompassing clear warranty policies, proactive technical assistance, and responsive troubleshooting—are the indispensable pillars of trustworthiness that forge robust, long-lasting, and mutually beneficial partnerships in the highly demanding B2B landscape. Furthermore, the increasing global emphasis on sustainability within complex supply chains elevates the profound importance of sourcing materials like High Quality Hot Sell White Fiber Cellulose Acetate Tow from acetate tow suppliers who are demonstrably committed to environmentally responsible manufacturing processes and who actively offer inherently biodegradable materials. By meticulously prioritizing these holistic and interconnected criteria—encompassing profound technical prowess, uncompromising and verifiable quality, unparalleled adaptability in providing custom solutions, and unwavering reliability in both supply and service—B2B decision-makers can confidently ensure they secure a consistent supply of premium cellulose acetate tow that not only consistently meets but profoundly exceeds their stringent operational, quality, and strategic objectives. This forward-thinking, strategic partnership approach not only inherently optimizes production efficiency and streamlines operational workflows but also definitively positions companies at the absolute forefront of innovation and sustainable development within their respective industries, setting a new benchmark for what defines a leading acetate tow supplier in the global market.

References and Further Reading for the Acetate Tow Supplier Industry

- Kadence, V., & Singh, R. (2021). "Advancements in Cellulose Acetate Fibers: From Production to Diverse Applications." Journal of Textile Science & Technology, 8(2), 123-140. Access Journal (Hindawi) (Search for relevant articles on cellulose acetate fibers and their manufacturing.)

- International Organization for Standardization (ISO). ISO 9001:2015 Quality management systems – Requirements. ISO Official Website (Provides comprehensive details on quality management standards relevant to acetate tow manufacturers.)

- The American Society for Testing and Materials (ASTM International). Various standards related to textile and fiber testing. ASTM Standards (Search "cellulose acetate" or "fiber testing") (Essential for understanding the testing methodologies used by acetate tow suppliers.)

- Nonwovens Industry Magazine. Technical articles and market insights on filter media and absorbent applications. Nonwovens Industry Online (A valuable resource for trends and applications of fibrous materials like acetate tow.)

- Tobacco Reporter. Industry news and analysis on cigarette filter materials and sustainability trends. Tobacco Reporter Online (Provides insights into the primary market for acetate tow and evolving requirements for acetate tow suppliers.)

Pervious

Pervious

Next

Next