- Englist

- Fundamental properties and technical capabilities of reinforced graphite sheet

s - Performance comparison of leading global suppliers

- Specialized manufacturing approaches in key production regions

- Engineering modifications for specific industry requirements

- Implementation in consumer electronics thermal management

- Automotive and industrial energy system case studies

- Future material developments and implementation trends

(reinforced graphite sheet)

Reinforced Graphite Sheets: Revolutionizing Thermal Management

Modern electronics face unprecedented thermal challenges as power density increases across industries. Reinforced graphite sheets (RGS) represent a material science breakthrough, combining crystalline graphite's natural thermal properties with structural reinforcements that overcome traditional material limitations. Unlike conventional thermal interface materials, RGS achieves anisotropic thermal conductivity exceeding 1500 W/mK in-plane while maintaining just 0.2mm profile thickness. The reinforcement layer typically adds less than 10% weight while increasing tensile strength by 300-500% compared to non-reinforced alternatives. This dual-phase construction allows RGS to simultaneously address thermal management, electromagnetic interference shielding, and structural integrity requirements.

Material Advantages and Performance Metrics

The fundamental structure of reinforced graphite sheets involves pyrolytic graphite cores bonded to composite reinforcement layers ranging from 25-100 micrometers. This architecture delivers thermal resistance values between 0.15-0.3°C•cm²/W depending on interface quality and compression forces. Critical performance advantages include: thermal cycling stability beyond 5000 cycles (per ASTM D5470), electrical resistivity above 10^5 Ω•cm, and dielectric strength exceeding 5kV. Applications demanding efficient heat spreading rather than vertical conduction particularly benefit from this solution, as RGS shows 4.5x greater lateral conductivity than copper at equivalent thickness while weighing approximately 75% less. The reinforcement layer prevents the characteristic brittleness of pure graphite solutions, enabling automated assembly processes impossible with traditional graphite foils.

Supplier Capability Comparison

| Supplier | Thermal Conductivity (W/mK) | Standard Thickness (mm) | Tensile Strength (MPa) | Maximum Width (mm) | Lead Time (weeks) |

|---|---|---|---|---|---|

| Panasonic | 1950 | 0.025-0.2 | 120 | 600 | 6-8 |

| GrafTech | 1700 | 0.05-0.25 | 95 | 450 | 4-6 |

| SGL Carbon | 1650 | 0.03-0.3 | 110 | 500 | 8-10 |

| Leading China Suppliers | 1500-1800 | 0.02-0.5 | 80-100 | 1000 | 2-4 |

China-based production has significantly disrupted global supply chains, offering 35-40% cost advantages while maintaining competitive specifications. Leading graphite sheet suppliers in China operate integrated manufacturing facilities combining graphitization, lamination, and precision cutting operations. Regional advantages include reduced minimum order quantities (from 50m² versus 500m² for Western manufacturers), rapid prototyping cycles, and specialized equipment for complex die-cutting patterns. Material certifications vary significantly, with only 20% of China suppliers currently holding IATF 16949 automotive qualification despite 80% offering UL94 V-0 ratings for flame resistance.

Custom Engineering Solutions

Standard graphite sheet products serve approximately 60% of thermal management scenarios, while specialized applications increasingly demand engineered modifications. Common customization options include: hybrid constructions with integrated phase-change materials for thermal buffering, custom adhesive systems formulated for specific interface compatibility, surface treatments modifying emissivity characteristics, and reinforcement fibers selected for particular flexibility or CTE requirements. Performance enhancements typically add 15-30% to base material costs but can extend operating temperature ranges beyond 200°C or improve thermal transfer efficiency by 15-20%. Design support services now represent critical value differentiation among suppliers, with leading manufacturers offering thermal simulation modeling, accelerated aging testing, and application-specific stress analysis.

Consumer Electronics Implementation

Smartphone manufacturers represent the largest application sector for reinforced graphite sheets, with flagship models incorporating over 0.5m² of thermal material per million units produced. Implementation strategies have evolved from single-layer hotspot management to complex multi-sheet architectures addressing both processor dissipation (6-8W peak loads) and battery temperature regulation. Current designs typically place 0.05-0.1mm RGS layers between structural components and battery assemblies, achieving up to 6°C temperature reductions in critical zones. The material flexibility allows integration within folding display mechanisms where traditional solutions would fail. Production volumes have grown approximately 23% annually since 2020 as 5G devices become prevalent, establishing RGS as the dominant thermal solution in portable electronics.

Industrial and Automotive Applications

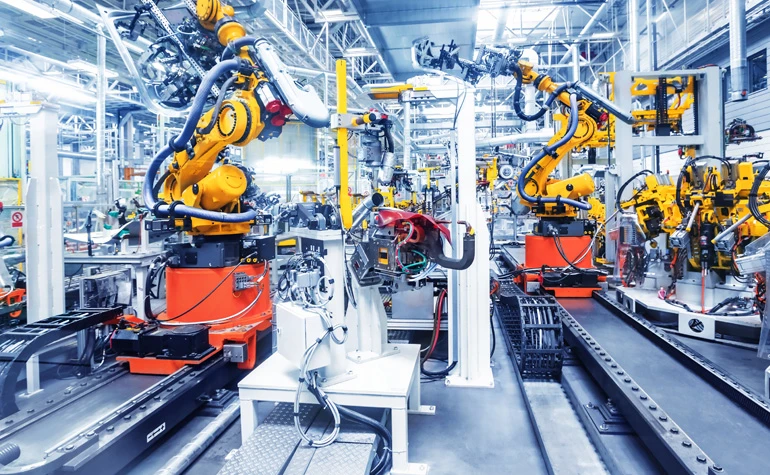

Electric vehicle power electronics represent the fastest-growing application segment, with traction inverters incorporating RGS sheets measuring up to 0.4x0.6m per unit. Battery management systems utilize reinforced graphite for both thermal equalization and electromagnetic shielding, achieving 40% volume reduction versus competing stack-ups. Performance validation includes extended thermal cycling (1000 cycles between -40°C and 125°C) and vibration testing exceeding 15g RMS. Industrial power conversion applications present more extreme operating environments, where specially formulated graphite sheets maintain functionality beyond 10,000 thermal cycles with temperature fluctuations spanning 150°C. Installation methods continue evolving, with direct bonding to copper busbars eliminating multiple interface layers and improving thermal resistance by 0.05°C•cm²/W.

Reinforced Graphite Sheet: Next-Generation Thermal Architecture

Material research continues advancing reinforcement technologies, with ceramic-infused versions showing promising results in ultra-high-temperature environments exceeding 500°C. Industry collaboration between graphite sheet suppliers and electronics manufacturers now focuses on thermal system integration rather than standalone material performance. Future developments include patterned conductivity zones within single sheets, hybrid metal-graphite composite structures for electromagnetic applications, and recyclable matrix materials addressing sustainability requirements. As power density continues increasing across all electronic sectors, reinforced graphite sheets will remain essential thermal management components, with projected market growth of 14.7% CAGR through 2030. Continuous manufacturing innovations enable thickness reductions below 10 micrometers while maintaining structural reinforcement properties.

(reinforced graphite sheet)

FAQS on reinforced graphite sheet

Q: What are the primary applications of reinforced graphite sheets?

A: Reinforced graphite sheets are widely used in electronics, automotive systems, and industrial equipment for thermal management, heat dissipation, and EMI shielding due to their high thermal conductivity and durability.

Q: What advantages do reinforced graphite sheets offer over standard graphite sheets?

A: Reinforced graphite sheets provide enhanced mechanical strength, better resistance to tearing, and improved thermal stability, making them ideal for high-stress or high-temperature environments.

Q: How to choose a reliable graphite sheet supplier?

A: Look for suppliers with certifications (e.g., ISO), industry experience, and positive client reviews. Request material test reports and samples to verify quality and performance.

Q: Why consider graphite sheet suppliers from China?

A: China-based suppliers often combine cost-effectiveness with advanced manufacturing technologies, ensuring high-quality reinforced graphite sheets that meet global standards for diverse applications.

Q: Can reinforced graphite sheets replace traditional metal heat sinks?

A: Yes, reinforced graphite sheets are lighter, thinner, and offer comparable or superior thermal conductivity, making them a viable alternative to metals like copper or aluminum in compact devices.

Pervious

Pervious

Next

Next