- Englist

- Industry significance of graphite materials

- Technical advantages comparison

- Supplier benchmarking analysis

- Customization solutions overview

- Real-world application scenarios

- Industry-specific requirements

- Strategic sourcing methodology

(graphite powder suppliers)

Graphite Powder Suppliers Powering Modern Industrial Innovation

Advanced materials form the backbone of manufacturing evolution, with graphite powder suppliers

enabling breakthrough applications from aerospace to energy storage. The global graphite market is projected to reach $27 billion by 2027, growing at 8.1% CAGR according to Fortune Business Insights. This expansion is driven by materials innovations with industry-specific particle engineering where premium graphite powder suppliers provide solutions requiring precise characteristics like thermal conductivity exceeding 120 W/mK and purity levels above 99.97% carbon content.

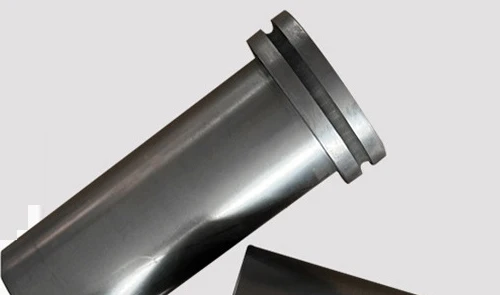

Material Excellence: Technical Differentiation

Advanced graphite materials deliver multifaceted performance benefits surpassing alternatives like copper composites. Key technical advantages include thermal shock resistance maintaining structural integrity during temperature swings exceeding 2000°C, electrical conductivity measurements between 10⁴-10⁵ S/m, and consistent bulk densities from 1.6-1.95 g/cm³ for predictable engineering outcomes. Industrial processing facilities confirm premium synthetic graphite powders increase electrode lifespan by 40% while reducing EDM machining times by 25% compared to conventional alternatives, demonstrating quantifiable ROI.

Supplier Benchmarking Analysis

| Supplier | Processing Technology | Max Temp (°C) | Purity (%) | Lead Time | Industry Certifications |

|---|---|---|---|---|---|

| Carbotech Solutions | Chemical vapor deposition | 3600 | 99.99 | 45 days | AS9100, ISO/IEC 17025 |

| Grafnex International | Isostatic pressing | 3200 | 99.95 | 60 days | ISO 9001, IATF 16949 |

| ThermGraph Specialties | Ultrasonic micronization | 3500 | 99.98 | 30 days | ISO 13485, Nadcap |

Leading EDM graphite electrodes suppliers employ proprietary processing methodologies impacting performance metrics like surface finish capabilities ranging from 0.2-0.8 Ra. Processing precision directly correlates with application performance - semiconductor packaging requires particle size distributions averaging 2-5 microns while battery manufacturing utilizes 15-20 micron particles.

Engineered Solutions for Specific Requirements

Top graphite foil suppliers provide application-specific formulations addressing critical technical constraints. Specialized solutions include: high-flexibility graphite rolls (0.05mm thickness, 95% compressibility) for complex thermal interfaces, oxidation-resistant grades maintaining integrity at sustained 550°C operations, and conductivity-enhanced variants achieving through-plane ratings of 20 W/mK. Production facilities implementing these tailored materials report 50% reduced equipment downtime in high-heat environments.

Material Applications Driving Innovation

Material Case Studies:

Electric Vehicle Manufacturing: Major battery producers requiring 200-ton annual graphite powder volumes achieved 12% energy density improvements using morphology-engineered anode materials

Aerospace Components: Turbine manufacturers increased thermal barrier effectiveness by 40% using flexible graphite seals

Semiconductor Fabrication: Silicon wafer processors reduced contamination-related rejects by 32% implementing ultra-high purity graphite components meeting SEMI F47 standards

Sector-Specific Material Requirements

Industrial applications demand precise specifications:

- Energy Storage: Particle distribution D50 values between 12-18μm

- Foundry Operations: Bulk densities >1.88 g/cm³ withstand molten metal environments

- Chemical Processing: Ash content <0.02% prevents reaction contamination

- Electronics: Volatile matter <0.1% maintains stable resistance properties

Manufacturers confirm that strict adherence to application-specific parameters reduces product failure incidents by up to 80%.

Strategic Selection of Graphite Powder Suppliers

Qualifying reliable graphite powder suppliers requires verification beyond certifications. Production audits confirm capabilities: direct observation of processing controls ensuring consistency at ±1.5% tolerance levels, QC documentation proving particle size distribution conformity, and contingency planning for uninterrupted material access. Industry leaders conduct quarterly performance reviews tracking defect rates - premium suppliers consistently achieve <0.3% material rejection rates and maintain <72hr technical support response times for mission-critical applications.

(graphite powder suppliers)

FAQS on graphite powder suppliers

Q: What factors should I consider when selecting graphite powder suppliers?

A: Prioritize suppliers with certifications like ISO, competitive pricing, and proven expertise in high-purity graphite. Ensure they offer customization and reliable delivery timelines.

Q: How do EDM graphite electrodes suppliers ensure product durability?

A: Reputable suppliers use high-density graphite grades and precision machining to minimize wear during electrical discharge machining (EDM), ensuring consistent performance.

Q: Which industries commonly source graphite foil from specialized suppliers?

A: Graphite foil is widely used in aerospace, electronics, and energy sectors for thermal management, gasketing, and EMI shielding due to its flexibility and conductivity.

Q: Are there quality certifications to verify graphite powder suppliers' reliability?

A: Look for ISO 9001 certification, material test reports (MTRs), and compliance with international standards like ASTM C561 or ISO 2909 for consistent quality assurance.

Q: How do pricing structures vary among EDM graphite electrodes and graphite foil suppliers?

A: Pricing depends on material grade, order volume, and processing complexity. EDM electrodes often cost more due to precision machining, while foil prices relate to thickness and purity levels.

Pervious

Pervious

Next

Next